- Joined

- Nov 18, 2012

- Messages

- 1,352

Hi folks, my name is David. I am from Canada ...eh.

After reading the thread from Bernard (aka Dranreb) about making his larger cross feed dial, I decided it was time to try and do something with the tiny one on my Atlas 618. My objects were:

1 No permanent change / alteration to the 618

2 100% reversible

3 No buying anything.. must be made from shop supplies.

4 Functional.. of course.

Materials at hand: aluminum 6061-T6, free machining brass rod, all sorts of fasteners etc.

So here we go.

The first thing is to extend the dial pointer forward so that the dial can clear the cross slide. With the present 618 the clearance between the bottom of the cross slide and the pointer is around 0.008" on my lathe.

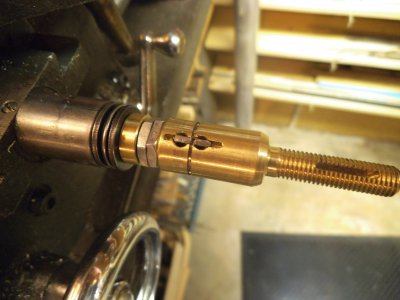

I decided that the ultimate diameter of the dial and pointer dial would be just under 2". So I started with the pointer, making an extension that would slip fit over the existing pointer, and milling a flat so that the cross slide would clear it. See first pic.

I milled it down until the web was about 0.010" and then hand filed the flat so that it would clear the slide. I wanted to keep some material there so that swarf wouldn't get into the lead screw thrust bearing. On the end facing us I drilled and tapped for three set screws, one on either side and one on the bottom.

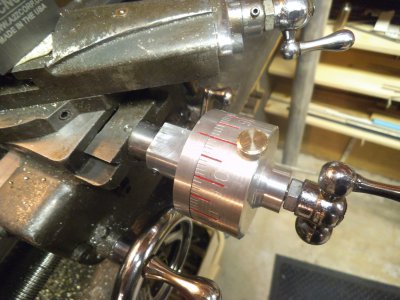

Next will come the lead screw shaft extension. I am not sure if there is a time out for doing posts, so will break it up.

After reading the thread from Bernard (aka Dranreb) about making his larger cross feed dial, I decided it was time to try and do something with the tiny one on my Atlas 618. My objects were:

1 No permanent change / alteration to the 618

2 100% reversible

3 No buying anything.. must be made from shop supplies.

4 Functional.. of course.

Materials at hand: aluminum 6061-T6, free machining brass rod, all sorts of fasteners etc.

So here we go.

The first thing is to extend the dial pointer forward so that the dial can clear the cross slide. With the present 618 the clearance between the bottom of the cross slide and the pointer is around 0.008" on my lathe.

I decided that the ultimate diameter of the dial and pointer dial would be just under 2". So I started with the pointer, making an extension that would slip fit over the existing pointer, and milling a flat so that the cross slide would clear it. See first pic.

I milled it down until the web was about 0.010" and then hand filed the flat so that it would clear the slide. I wanted to keep some material there so that swarf wouldn't get into the lead screw thrust bearing. On the end facing us I drilled and tapped for three set screws, one on either side and one on the bottom.

Next will come the lead screw shaft extension. I am not sure if there is a time out for doing posts, so will break it up.