-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lead screw / Halfnut adjustment

- Thread starter Dman1114

- Start date

- Joined

- Nov 16, 2012

- Messages

- 5,596

i just tightened it up with .028 on a feeler gauge and its perfect...

Looks like i gotta find me a .028 shim

Some halfnut mechanisms have an adjustable bolting mechanism. In the absence of that, your shim will probably do just fine.

Good job seeking and destroying a little glitch.

Ray

- Joined

- Oct 17, 2012

- Messages

- 126

and my JET 13X40 leaks also. Here's how it started:

I was studiously replacing pins and bushings for my old loader due to all the debris caused by the tornado here at Remlap, Al. See photo 1 & 2. As I was turning the end pin threads, well the first cut looked great. 2nd missed at half anic:

anic: anic:

anic: anic: thread. So I started 3rd. Kabang! The half nut lever went to 6:00 instead of 3:00 when I employed it. I mean straight down. Well after talking to some authorities, I am at stage photo 3 and 4. From the parts list I think the keyed shaft below lead screw must come loose, not sure. The parts list calls out the left side pinned and a clutch. Possibly a gremlin, see photo 4, showed up on the top of half nut dovetail housing. Hmmm. So guess, what leaks get fixed also.

anic: thread. So I started 3rd. Kabang! The half nut lever went to 6:00 instead of 3:00 when I employed it. I mean straight down. Well after talking to some authorities, I am at stage photo 3 and 4. From the parts list I think the keyed shaft below lead screw must come loose, not sure. The parts list calls out the left side pinned and a clutch. Possibly a gremlin, see photo 4, showed up on the top of half nut dovetail housing. Hmmm. So guess, what leaks get fixed also.

is this really fair? I will keep you informed. I photoed the "clutch".

Later on that.

Walter Meir indicated the half nuts are 8 wks out. They have always been hard to engage.

Not my best friends anyway.

JMH

I was studiously replacing pins and bushings for my old loader due to all the debris caused by the tornado here at Remlap, Al. See photo 1 & 2. As I was turning the end pin threads, well the first cut looked great. 2nd missed at half

is this really fair? I will keep you informed. I photoed the "clutch".

Later on that.

Walter Meir indicated the half nuts are 8 wks out. They have always been hard to engage.

Not my best friends anyway.

JMH

- Joined

- Oct 17, 2012

- Messages

- 126

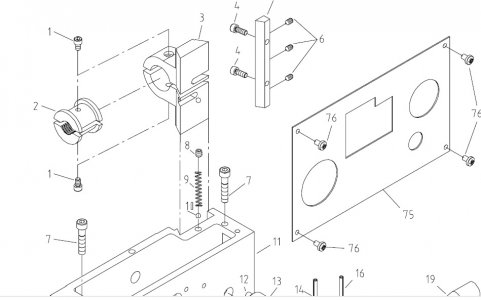

Progress on the Halfnut adjustment issue was made today. The apron has been removed and the leak culprit identified.

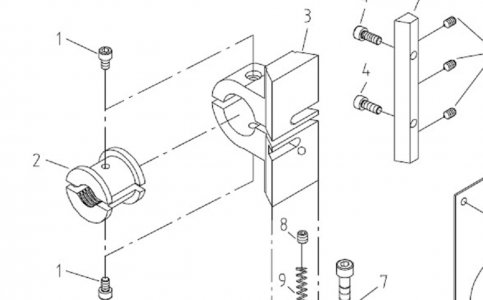

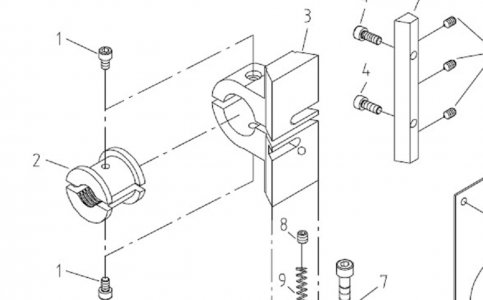

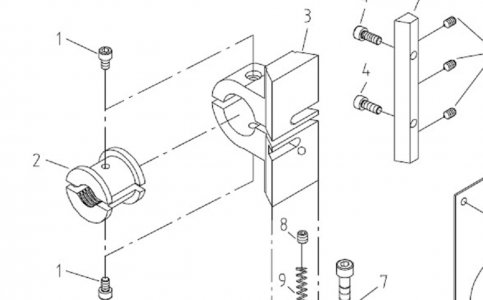

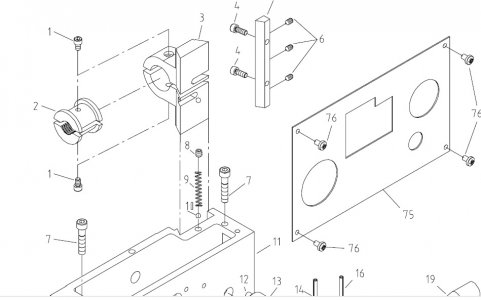

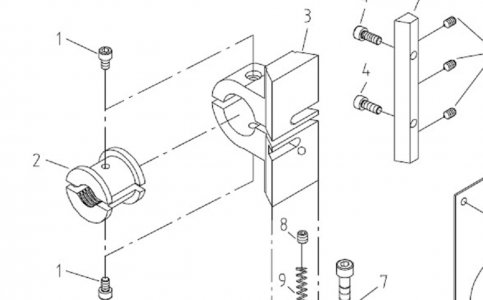

this is the half nut detail. It is adjustable for vertical. The half nut is bronze and the housing(carrier) is gray iron, not nodular iron.

I removed the end block and moved carriage/apron to the tailstock side. After removing the carriage head screws form the top of the carriage/cross slide the apron dropped free with shaft. The top rod is the lead screw. The middle rod is clutched on the left side and is driven by the half nut.

this is a photo of the nut assembly (HNA) and the rear of the apron:

The brittle cast iron prematurely failed. Nodular would not. The camshaft that closes the HNA is steel with 0.20" pins, on the left side of photo. The thin section of gray iron broke under my load, possibly due to my misuse and possible misalignment. Regardless at this time I am reluctant to purchase new parts and considering hiring someone to make them for me. Anyone interested?

However:

While down:

1) build a vernier for the compound

2) put a seal of somekind on the leaking lower shaft as it penetrates the case.

Further I need to find a good "sticking" grease.

Thanks to those that encouraged me to proceed. Just the unknown.....

Mike

this is the half nut detail. It is adjustable for vertical. The half nut is bronze and the housing(carrier) is gray iron, not nodular iron.

I removed the end block and moved carriage/apron to the tailstock side. After removing the carriage head screws form the top of the carriage/cross slide the apron dropped free with shaft. The top rod is the lead screw. The middle rod is clutched on the left side and is driven by the half nut.

this is a photo of the nut assembly (HNA) and the rear of the apron:

The brittle cast iron prematurely failed. Nodular would not. The camshaft that closes the HNA is steel with 0.20" pins, on the left side of photo. The thin section of gray iron broke under my load, possibly due to my misuse and possible misalignment. Regardless at this time I am reluctant to purchase new parts and considering hiring someone to make them for me. Anyone interested?

However:

While down:

1) build a vernier for the compound

2) put a seal of somekind on the leaking lower shaft as it penetrates the case.

Further I need to find a good "sticking" grease.

Thanks to those that encouraged me to proceed. Just the unknown.....

Mike

Hi, I have a lathe that looks exactly like that, Mine is a 95. If the spindle speed chart and the others on the front are in good shape on yours could you take a picture of each. Mine are worn off in places and I want to print out a copy to keep by the lathe

Thanks

Dave

Thanks

Dave