I feel like I'm going crazy but when I engage the power feed on my SB 14.5 it cuts a thread in stead of slowly feeding. I'm planning on taking the Apron and Saddle apart this weekend regardless because the poor thing has seen better days and definitely needs some love but before I do, has anyone ever experienced this before?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathe Power Feed cuts threads?

- Thread starter Seuss54

- Start date

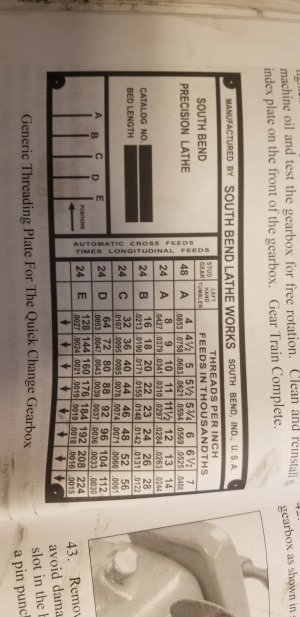

This is the result of using the power feed, the right most portion of the part is from a previous operation so it's smooth but it was done by hand, the banded portion was cut only using the power feed. The additional picture is of the current setup on the gearbox, unless I'm reading the charts wrong I should be feeding at like .0015 when I engage the clutch.

This is the result of using the power feed, the right most portion of the part is from a previous operation so it's smooth but it was done by hand, the banded portion was cut only using the power feed. The additional picture is of the current setup on the gearbox, unless I'm reading the charts wrong I should be feeding at like .0015 when I engage the clutch.Attachments

- Joined

- Oct 14, 2013

- Messages

- 1,252

You might be engaging the half nuts instead of the feed clutch... mine has an interlock between them.

Sent from my SM-S911U using Tapatalk

Sent from my SM-S911U using Tapatalk

- Joined

- Nov 24, 2014

- Messages

- 3,482

Every power feed is "N" amount of tool motion per spindle revolution.

Your "thread" issue is simply that you are using a relatively large tool motion with a relatively sharp pointed tool (looks like a "thread").

Reduce your feed per RPM (Quick Change Gear Box, QCGB) and/or present a less pointed tool to the workpiece.

Your "thread" issue is simply that you are using a relatively large tool motion with a relatively sharp pointed tool (looks like a "thread").

Reduce your feed per RPM (Quick Change Gear Box, QCGB) and/or present a less pointed tool to the workpiece.

Interesting. It doesnt look like the half nut is engaging as the lever wont move when the power feed lever is out of neutral. Maybe I'll have to look and see about this interlock.You might be engaging the half nuts instead of the feed clutch... mine has an interlock between them.

Sent from my SM-S911U using Tapatalk

Looks like the 1/2 nuts are in use.

The lever on the right controls the feed choice.

It should be 3 positions.

Down is half nuts.

Middle is power feed, up is cross feed if I recall correctly.

The clutch lever bottom center controls the action, on or off.

Sent from my SM-G781V using Tapatalk

The lever on the right controls the feed choice.

It should be 3 positions.

Down is half nuts.

Middle is power feed, up is cross feed if I recall correctly.

The clutch lever bottom center controls the action, on or off.

Sent from my SM-G781V using Tapatalk

- Joined

- Nov 24, 2014

- Messages

- 3,482

Post a picture of the feed chart.

It's got to be a lot of feed rate with the pictured tool/shallow cut or the half nuts. One or the other.

Measure the carriage travel per spindle revolution with a drop dial indicator and compare that number with the A+8 setting pictured on the QCGB.

It's got to be a lot of feed rate with the pictured tool/shallow cut or the half nuts. One or the other.

Measure the carriage travel per spindle revolution with a drop dial indicator and compare that number with the A+8 setting pictured on the QCGB.

Welp, I took another look at the feed chart and QCGB, I thought I was losing my mind not realizing I was on A not E. Boy do I feel dumb. The chart I have been using is out of the guide to renovating SB lathes. I think I need to look into getting a chart on the machine, unfortunately this machines chart went missing sometime during its life and the previous owner never needed it because he did most everything by hand.Post a picture of the feed chart.

It's got to be a lot of feed rate with the pictured tool/shallow cut or the half nuts. One or the other.

Measure the carriage travel per spindle revolution with a drop dial indicator and compare that number with the A+8 setting pictured on the QCGB.

Following up questions if I may:

1. The QCGB is awesome (if I dont forget to double check that I put the darn handles in the positions I want) but one of the gears (D iirc) has a broken tooth, any suggestions for a fix? Can I buy a new one or should I try and braze a new tooth on it?

2. Any ideas where I can purchase a nice chart to put on the lathe? For the time being I think I'll just print one off and laminate it but I'd like to restore this machine to a little closer to her original state, some things are busted and cant be helped but not everything.