- Joined

- Oct 7, 2020

- Messages

- 73

Sounds good, it will last you many years if you take care of it! The next thing is getting a millit is 9 inch swing 15 between centers but weight 1550 lbs so a lot of weight so it is sturdy

Sounds good, it will last you many years if you take care of it! The next thing is getting a millit is 9 inch swing 15 between centers but weight 1550 lbs so a lot of weight so it is sturdy

the next thing is a shop a two car garage that is packed full of stuff will get crowed and my neighbor needs parts machined and he does not have a lathe so that is the main reason and my dad is getting a shop built for him and me and my brother it should be done by springSounds good, it will last you many years if you take care of it! The next thing is getting a mill

Nice man, good luck with all!the next thing is a shop a two car garage that is packed full of stuff will get crowed and my neighbor needs parts machined and he does not have a lathe so that is the main reason and my dad is getting a shop built for him and me and my brother it should be done by spring

Thanks thats what i thoughtChange gear calculators are what you need:

Change Gears for Threading

This calculator determines the correct change gears for any thread pitch. Works for all mini lathes and HiTorque Bench Lathes.littlemachineshop.com

Though there are many more. It's not a straightforward single formula calculation and requires some iteration to get actual solutions.

It looks from the photos to be a 4tpi leadscrew. Are the crossfeed and compound handles graduated in inch or metric?

Jezz thanks so much kevin, it looks like you went out of your way!!I have a much smaller Atlas lathe and I ended up 3D printing change gears for it. Surprisingly, they have lasted a couple of years now.

If you can't find the exact model number, then you may have to be more creative. Do you have any gears for it now? If so, then you can figure out the gear pitch (or, rather, the metric equivalent), pressure angle, and hub diameter. I think the Machinist Handbook has detailed information. If you don't want plastic gears, then you may have to cut some from metal, or look for gears online fitting your specs.

I did some online research, and agree that there isn't much. Here is what I did find

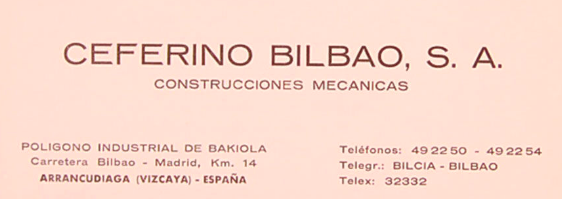

View attachment 354314

- Manufacturer seems to be CEFERINO BILBAO

- Here is an old catalog: https://www.worthpoint.com/worthopedia/vtg-ceferino-bilbao-catalog-bilcia-20-1856498703

- Apparently the Spanish term for lathe is: torno paralelo. I initially thought this might be manufacturer name, but it's not.

- Here is a manual on sale from ebay. Looks like a lot of money for not much... https://www.ebay.com/itm/Nordic-Cef...erations-and-Maintenance-Manual-/172760547040 However, the first page is shown and it contains an address, included below. I seemed to go down a rabbit hole pursuing the address

- Here is another HM thread about Bilcia lathes: https://www.hobby-machinist.com/threads/i-need-help.90093/

Best wishes,

Kevin

Getting the gears isn't the problem because i can actually make them/buy them, the spinde gear is 25 teeth, and the last gear (right before the gearbox chagne lever) is 100 tooth... Both weird ratios (for ke at least, i was used to my atlas 10 inchI have a much smaller Atlas lathe and I ended up 3D printing change gears for it. Surprisingly, they have lasted a couple of years now.

If you can't find the exact model number, then you may have to be more creative. Do you have any gears for it now? If so, then you can figure out the gear pitch (or, rather, the metric equivalent), pressure angle, and hub diameter. I think the Machinist Handbook has detailed information. If you don't want plastic gears, then you may have to cut some from metal, or look for gears online fitting your specs.

I did some online research, and agree that there isn't much. Here is what I did find

View attachment 354314

- Manufacturer seems to be CEFERINO BILBAO

- Here is an old catalog: https://www.worthpoint.com/worthopedia/vtg-ceferino-bilbao-catalog-bilcia-20-1856498703

- Apparently the Spanish term for lathe is: torno paralelo. I initially thought this might be manufacturer name, but it's not.

- Here is a manual on sale from ebay. Looks like a lot of money for not much... https://www.ebay.com/itm/Nordic-Cef...erations-and-Maintenance-Manual-/172760547040 However, the first page is shown and it contains an address, included below. I seemed to go down a rabbit hole pursuing the address

- Here is another HM thread about Bilcia lathes: https://www.hobby-machinist.com/threads/i-need-help.90093/

Best wishes,

Kevin