- Joined

- Aug 21, 2022

- Messages

- 53

Hello Gang

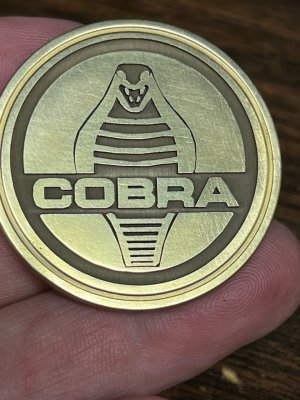

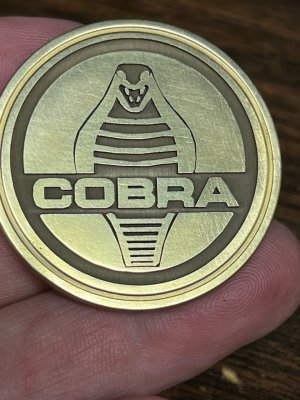

I am starting to do a few projects using my new LaserStar 50 watt fiber laser. I have engraved my name and phone number on most of my tools but now I am starting to make some items on my laser that I could possibly sell to someone. Here is my first shot at making Challenge coin. I am in a Shelby Cobra car club which is why I decided to make these as my first laser project. They are made out of brass and I got the blank coins on Amazon. I have some bronze coins on order but had to go to another supplier cuz Amazon does not carry blank ones.

Paul

I am starting to do a few projects using my new LaserStar 50 watt fiber laser. I have engraved my name and phone number on most of my tools but now I am starting to make some items on my laser that I could possibly sell to someone. Here is my first shot at making Challenge coin. I am in a Shelby Cobra car club which is why I decided to make these as my first laser project. They are made out of brass and I got the blank coins on Amazon. I have some bronze coins on order but had to go to another supplier cuz Amazon does not carry blank ones.

Paul