I think those stories need to stay with the machine.

Yeah I'll probably never sell the saw!

But if it ever gets handed down to a friend or someone in the family, I got a lot of pictures & details of it during the various stages of being rebuilt.

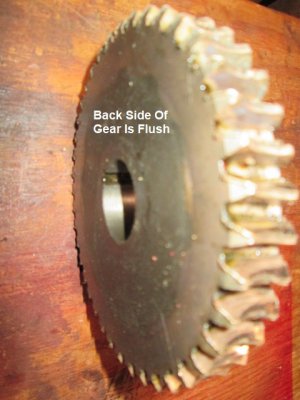

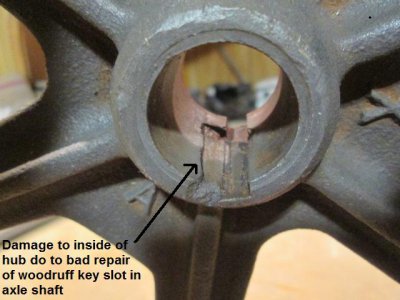

After I fixed the problems with the feed-rate & head-weight, Another problem the saw developed was a bad wobble in the drive wheel.

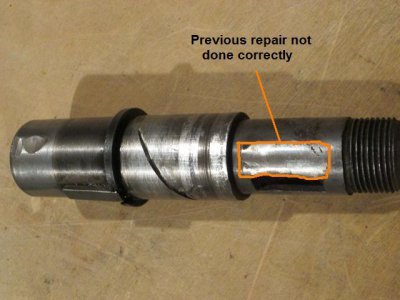

It turns out that this was caused by a previous poor repair job done at one time to the drive axle.

The poor axle repair job led to the wobbling problems with the drive wheel!

I found another gearbox & drive wheel for it on-line, However the axle on that one had what looked like a stress-crack on the righthand side of the woodruff key slot. Appling just a little bit of force with a screwdriver, The righthand side of the woodruff slot broke off.

Apparently when these saws are misused & the blade comes to a sudden stop, It damages the axle!

Unfourntaly I do not have a metal lathe & a mill to remake a new axle, So I was left to the Backyard Machinist or MacGyver method.

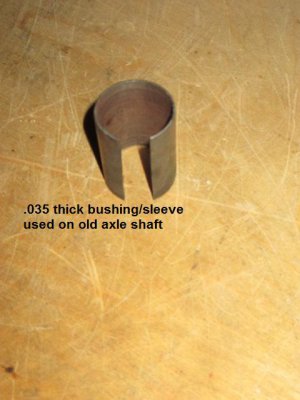

I managed to weld the broken piece back in-place & then I filled the old woodruff slot with weld. It was not the best looking weld since I was trying to minimize the heat to prevent any warping. There were a few very small areas that didn't get fully filled with weld, So I used the old stand by JB Weld to fill-in those areas. I used a small wood lathe to spin the axle & files to get it to size, Once I had it to size I used my drill press/mill to cut a new key-way slot on the opposite (good side) of the axle.

Doug