Ok folks, I hit a wall tonight.

Spent about 4 hours cleaning, and trying to fit the head stock and spindle parts for assembly. no joy. I was stumped.

took my time, lightly filed the burrs I found on the spindle (set screw damage from both bull and cone spindle pulley, the 2 keyways, and general abuse by some heavy handed PO) using a very light file, and some 400 grit, also very lightly), and checked the fit using the original sleeve bearings.

Installed the new headstock sleeve bearings into the headstock, which went pretty smoothly.

Then I installed new sleeve bearings for the new cone pulley I found (an M6-79, which I think was new old stock from somewhere, or lightly used. it still has casting marks/seams in the pulley sheaves). Oiled them with spindle oil, and pushed them in with wood/small hammer and some by hand.

I couldn't get this new spindle pulley with new sleeve bearings to fit on the spindle, although I didn't try very hard. It seemed to me that the spindle is going to be as tight a press fit as the cone pulley was, for it's sleeve bearings installed. the cone spindle pulley that came with the lathe seems to match the new pulley, but upon measuring, it is about 0.01" longer (end of gear to end of largest sheave). but the cone pulley sleeves pressed in about as I would have expected. nice and snug, but moved when tapped with a dowel/wood, and small hammer.

I didn't want to address that problem at the time, as I wanted to go through the entire process of fitting everything, so I grabbed the original spindle pulley. It slid on right up the shoulder of the bull gear diameter, possibly looser than I would want, but it would probably work fine.

I got the bull gear to slide on, and pressed the key into the keyway, and that all seemed to fit ok. Same as the original cone spindle pulley - it was possibly looser than I expected, but it would move on the shaft, and I didn't really feel any considerable play.

Got the new thrust bearing, and pushed that on. Rather snug fit, but it went on.

I then tried to go through the process of fitting it all together in the headstock, and for the life of me, the combination of the new bearing, new cone spindle pulley, and bull gear, barely fit into the headstock. Forget about space to move the bull gear. It has less than ~0.05" before it hits the indexing pin in the headstock.

The new INA D-5 bearing Clausing supplied is significantly thicker than the Nice 5774 that came with the lathe. So, I grabbed that bearing, and tried a test fit.

It's still way to tight, in my opinion. No room in the headstock. For sure there is no way I can get the bull gear key into it's keyway.

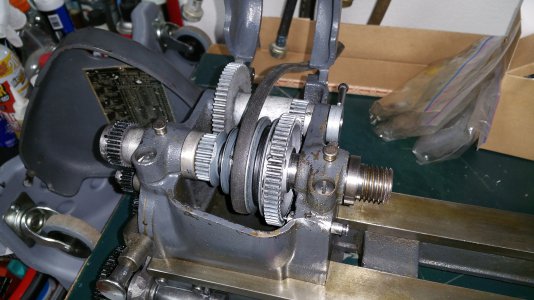

I checked the sleeve bearings - maybe they were protruding past the casting into the headstock space?...maybe .03-.05" for the left sleeve. I remedied that with some gentle whacks on a dowel. But it's still much too tight to get the bull gear key in (see pictures attached).

Also, the spindle is not fully inserted into the headstock, but that may be the issue of pressing the spindle into the inner race in the thrust bearing.

Either I've done something incredibly wrong or stupid, or maybe there is a version of the spindle pulley that is not as thick? I probably spent too much time with it, and am rather tired. But I made sure to stay patient and not rush or force anything... that said, I'm at a total loss as to what might be happening.

The picture below shows the orig. Nice thrust bearing, cone spindle pulley and bull gear all pushed as far over the left as possible. With the indexing pin all the way out, it's still almost touching.

Ideas and suggestions are massively welcome here!

Spent about 4 hours cleaning, and trying to fit the head stock and spindle parts for assembly. no joy. I was stumped.

took my time, lightly filed the burrs I found on the spindle (set screw damage from both bull and cone spindle pulley, the 2 keyways, and general abuse by some heavy handed PO) using a very light file, and some 400 grit, also very lightly), and checked the fit using the original sleeve bearings.

Installed the new headstock sleeve bearings into the headstock, which went pretty smoothly.

Then I installed new sleeve bearings for the new cone pulley I found (an M6-79, which I think was new old stock from somewhere, or lightly used. it still has casting marks/seams in the pulley sheaves). Oiled them with spindle oil, and pushed them in with wood/small hammer and some by hand.

I couldn't get this new spindle pulley with new sleeve bearings to fit on the spindle, although I didn't try very hard. It seemed to me that the spindle is going to be as tight a press fit as the cone pulley was, for it's sleeve bearings installed. the cone spindle pulley that came with the lathe seems to match the new pulley, but upon measuring, it is about 0.01" longer (end of gear to end of largest sheave). but the cone pulley sleeves pressed in about as I would have expected. nice and snug, but moved when tapped with a dowel/wood, and small hammer.

I didn't want to address that problem at the time, as I wanted to go through the entire process of fitting everything, so I grabbed the original spindle pulley. It slid on right up the shoulder of the bull gear diameter, possibly looser than I would want, but it would probably work fine.

I got the bull gear to slide on, and pressed the key into the keyway, and that all seemed to fit ok. Same as the original cone spindle pulley - it was possibly looser than I expected, but it would move on the shaft, and I didn't really feel any considerable play.

Got the new thrust bearing, and pushed that on. Rather snug fit, but it went on.

I then tried to go through the process of fitting it all together in the headstock, and for the life of me, the combination of the new bearing, new cone spindle pulley, and bull gear, barely fit into the headstock. Forget about space to move the bull gear. It has less than ~0.05" before it hits the indexing pin in the headstock.

The new INA D-5 bearing Clausing supplied is significantly thicker than the Nice 5774 that came with the lathe. So, I grabbed that bearing, and tried a test fit.

It's still way to tight, in my opinion. No room in the headstock. For sure there is no way I can get the bull gear key into it's keyway.

I checked the sleeve bearings - maybe they were protruding past the casting into the headstock space?...maybe .03-.05" for the left sleeve. I remedied that with some gentle whacks on a dowel. But it's still much too tight to get the bull gear key in (see pictures attached).

Also, the spindle is not fully inserted into the headstock, but that may be the issue of pressing the spindle into the inner race in the thrust bearing.

Either I've done something incredibly wrong or stupid, or maybe there is a version of the spindle pulley that is not as thick? I probably spent too much time with it, and am rather tired. But I made sure to stay patient and not rush or force anything... that said, I'm at a total loss as to what might be happening.

The picture below shows the orig. Nice thrust bearing, cone spindle pulley and bull gear all pushed as far over the left as possible. With the indexing pin all the way out, it's still almost touching.

Ideas and suggestions are massively welcome here!