- Joined

- Feb 27, 2023

- Messages

- 109

I'll take a look at my local auto parts store and see if they have any.My chip tray is from auto parts store for $10. It's used in home garage placed under the car to catch oil drips.

I'll take a look at my local auto parts store and see if they have any.My chip tray is from auto parts store for $10. It's used in home garage placed under the car to catch oil drips.

Honestly I just put the gears together and slowly move them back until there's a little play in between the teeth, sometimes I'm surprised when some people tell me they didn't realize that gears aren't supposed to fully mesh together. And I do technically have a milling machine but it's down in the shop and it's CNC, I would turn it back into a manual Mill but my grandad used various bits and pieces around the shop after he turned it into CNC. Now I can control the mill with a joystick controller but neither me or my granddad can figure out how to make one joystick for one axis and one for another, because at the moment one joystick controls both the up and down movement of the head and the table movement..Curios how you adjusted your gear train for meshing clearance? I use .002" typing paper strips for clearance adjustment.

Pretty sure your going to discover you'll "NEED" a milling machine. I bought a 1hp Grizzly milling machine and has worked really well for me. It was the cheapest 1hp mill I could find about 8 or so years ago and bought it new for $1500. I added on a shuttle which makes it less tiresome cranking the handle to move the table.

I would suggest you go back and use .002-.0025" paper to set the meshing of the gears. You will have noisy gears and early wear and failure of the gears otherwise. The gears have to have play in them and never fully meshed. I did notice your gears were a little noisey in your video. I lightly use 30w oil on the gears but gear lube is even better.Honestly I just put the gears together and slowly move them back until there's a little play in between the teeth, sometimes I'm surprised when some people tell me they didn't realize that gears aren't supposed to fully mesh together. And I do technically have a milling machine but it's down in the shop and it's CNC, I would turn it back into a manual Mill but my grandad used various bits and pieces around the shop after he turned it into CNC. Now I can control the mill with a joystick controller but neither me or my granddad can figure out how to make one joystick for one axis and one for another, because at the moment one joystick controls both the up and down movement of the head and the table movement..

Baking sheets are good too....I haven't run a survey to get real t numbers but I would guess that the number of actual factory chip trays belonging to members here is pretty small. Probably the majority of those who have one or more got them from either an auto parts or grocery store. The number of machines with a factory one is probably quite small. The main reason that I have one is because it came with my Atlas 3996 when I bought it new in early 1981.

Measure it and buy a stainless steel baking sheet/tray… I suggestion from this forum that I followed for two of my lathes. Those work great. Got mine from Amazon. They come in all sizes.Oh I've changed over to adjustable belts now and that thing looks really good, makes me wish I had a chip tray

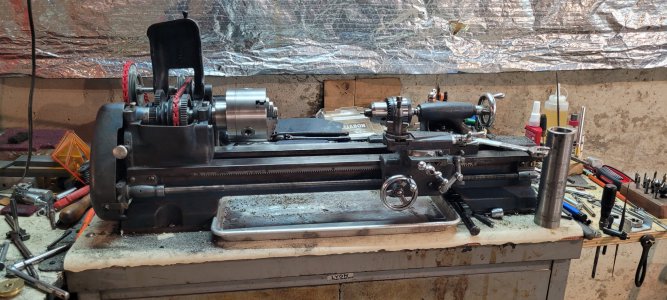

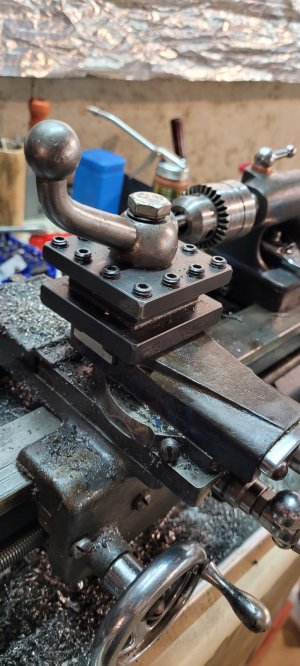

Oh, yeah I've got some updates. I was just busy and got sick, So I've got a chip tray now and I got the three jaw chuck adapted onto it now and I'm in the works of getting a Dro attached to the Cross slide and the carriage. Oh oh and I also got my four-way tool post adapted onto it.Have any updates for us?