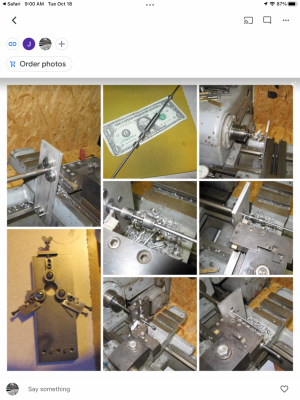

Delrin melts due to friction easily. This is a very old-school thing I was shown in the early 70s. It is very effective for a variety of things, such as cutting E-clip grooves in small diameter material. Phenolic has high heat tolerance. (that's why it was used in circuit boards in high heat tube days, long before g10 epoxy and transistors).

No worries about dust here. It doesn't break down hardly at all. I have used this on smooth 1/8" shafts for cutting hundreds of grooves, and never needed adjusting, so minuscule wear.