Here are some pics of my new baby. Sorry about the blurryness - trying to hold still while taking a pic and holding a shop light at the same time. I've powered it up and it sounds good and fairly quiet with just the spindle running. More gear noise with the power feed drive engaged, but no "bad" sounds (clunk, squeal, screech, etc). Both feeds work as does the threading feed. The quick change is a little sticky but works properly as far as I can tell. No back gears which seems weird. Also, no reversing switch - not sure if that is important.

I would like some advice on what I should disassemble to check and clean everything - if there is a best order for disassembly or stuff I just should not mess with. Also what is an appropriate cleaning fluid and subsequent lubricant for the various mechanisms. Any and All advice would be HUGELY appreciated!!

Thanks for looking.

My new toy!!! I think it is a 1982 vintage machine. 1236P

The headstock gears all look to be in good shape; no missing or worn looking teeth.

Missing the back gears though; not sure why anyone would remove those.

All the gears here are in good shape too. Lots of grease and gunk though. From what I've read grease is not the proper lubricant here. Can someone suggest what I should use once I clean these up??

Also, not sure what the large outboard gear is for; doesn't seem to be another gear for it to engage with. Is something missing from the banjo??

I think the ways look pretty good; what do you guys think? No obvious dings and the saddle moves pretty smooth for most of the travel; gets a little tighter near the last 8" by the tailstock.

Lead screw threads still look "square" with no dings.

Ways near the headstock.

The power feed selector (cross or linear) is kind of sticky, but both feeds work fine. Do I need to disassemble the saddle and cross slides to clean it up? Not sure where to start with that and don't want to end up finding out "oh crap, you should never have taken that apart

".

Can anyone explain this chuck to me? No T-handle to tighten it, but it has this knurled outer ring with dog holes around the perimeter. There is a short bar that fits the dog holes and presumably is for tightening the chuck jaws. Can't figure out how to lock the spindle to turn the knurled collar or which direction it should turn and I don't want to damage anything. Need some advice here.

The "tool"

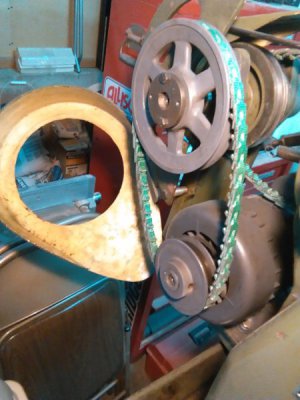

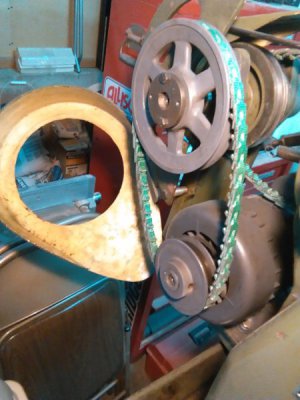

The "extra" drive gear. Anyone know what it's for or if there is another gear or two missing?

No slow speed pulley. Missing both stepped pulleys - does anyone have a source for these or at least a size for the motor pulley and the intermediate shaft pulley?

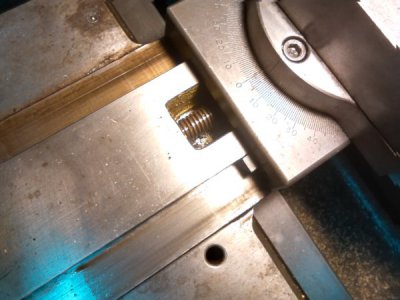

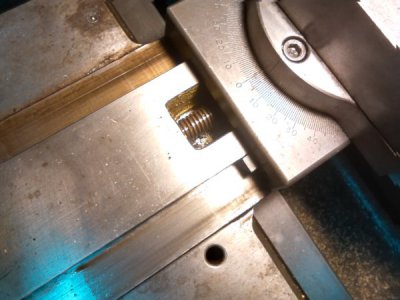

Cross slide ways and leadscrew. The cross moves pretty smooth through the entire travel. Look OK to you guys?

Cross slide ways

Compound ways. Those are old chips on the surface. Compound is pretty tight throughout it's travel. I think there is a jib screw near the crank. Does that just need a little adjustment to loosen it up a bit?

).

). ).

).

".

".