- Joined

- Sep 20, 2012

- Messages

- 560

A few years ago I made a repair to my gear case, this survived well until the other week I noticed it was moving again, a close look showed that a new crack had appeared across the other side of the part: http://www.hobby-machinist.com/showthread.php/9309-Atlas-apron-gear-case-10F-11-repair

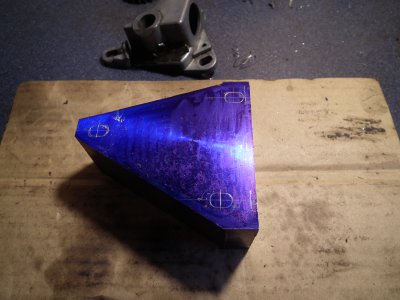

Something better had to be done so as I had a lump of ally handy I got started, excuse the state of my saw, had it for 20 odd years on site work and it now lives behind my miter saw..

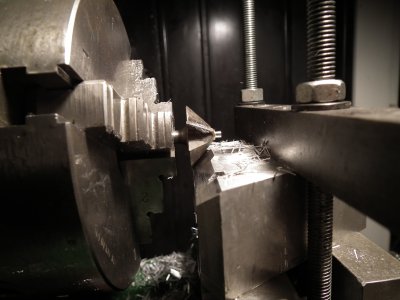

This was my first mistake, my inexperience showing here!

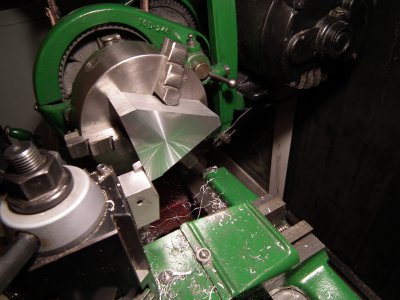

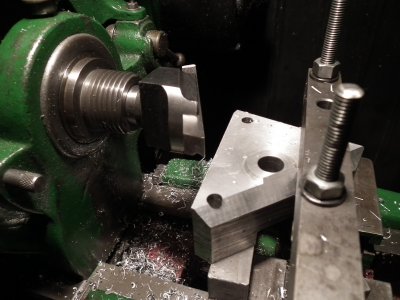

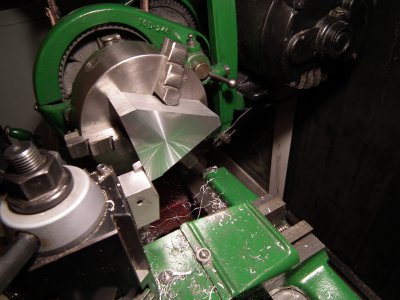

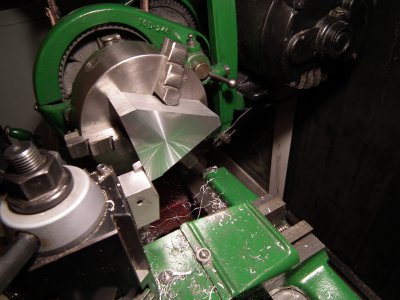

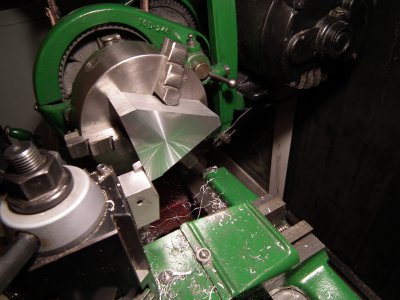

Faced it off in 3 jaw.

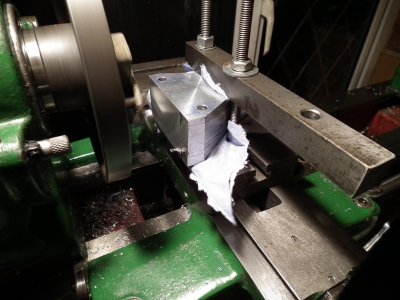

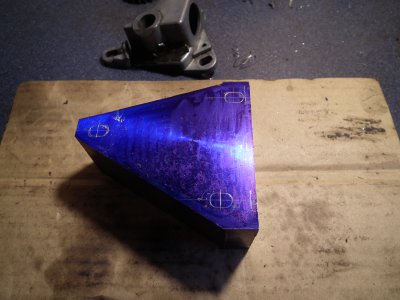

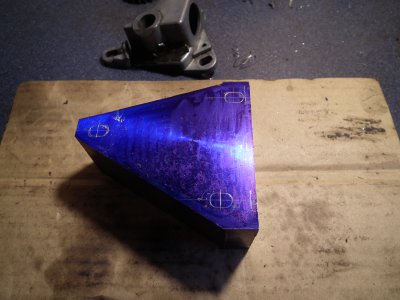

Laid a broken spare case on and marked the slotted holes.

Transferred the centres around to the other side.

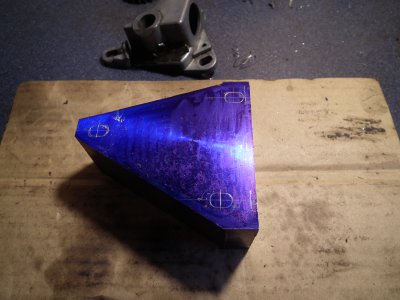

Drilled holes and trial fit, so far so good.

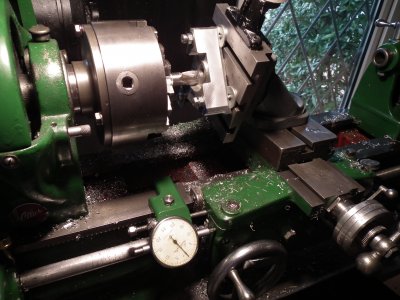

Made a transfer guide by trial and error to mark the spindle hole.

As you can see this is just SOTP engineering, no actual measuring has been done yet, a bit like drawing around my hand and tracing when I was a kid, that's still working for me!

Bernard

[h=2][/h]

Something better had to be done so as I had a lump of ally handy I got started, excuse the state of my saw, had it for 20 odd years on site work and it now lives behind my miter saw..

This was my first mistake, my inexperience showing here!

Faced it off in 3 jaw.

Laid a broken spare case on and marked the slotted holes.

Transferred the centres around to the other side.

Drilled holes and trial fit, so far so good.

Made a transfer guide by trial and error to mark the spindle hole.

As you can see this is just SOTP engineering, no actual measuring has been done yet, a bit like drawing around my hand and tracing when I was a kid, that's still working for me!

Bernard

[h=2][/h]