- Joined

- May 12, 2019

- Messages

- 15

Hey all! I did some basic machining in college on full sized equipment about 15 years ago in engineering school. I still tinker with all sorts of things around in my home shop and came across an opportunity to pick up a Grizzly G0704 7x27” 1HP R8 Mill and a G4000 9x19” 3/4HP lathe second hand locally. Small home shop sized things don't come up often in my area so i jumped on it. Both came basically unused (but older) with a decent set of starter tooling and I've picked up some stuff along the way. So far I tore each down, cleaned them up, and re-lubed everything. I’m sure I still have some adjustments to do but everything seems to be working as intended (well for an import machine). Please excuse the mess... generally its quite a bit more tidy but I'm between projects.

I have no particular projects in mind. Just hobbies or parts that could be useful in my regular putzing around in the shop or restoring old equipment. I’ll probably make a few upgrade parts for the machines first. I already added an OXO QCTP to the lathe and machined a female threaded bolt to interface with the existing stud. (Pictured). Potential next improvements:

QCTP Machined female bolt (made from leftover suspension bolt because I dont throw anything out)

Fitment

I recently scooped up a endmill lot from a local guy. It's mainly carbide from Data Flute, Garr, Duramill, and Niagara. I’d say some of it looks new or still sharp, some used, and some a victim of poor storage and transport. I cleaned and lubed them up (although used an oiled rag which left some minor lint in the pictures). I’d wager some of the larger ones outsize my mill’s motor and rigidity. I know carbide is able to run a lot faster/harder in general at any size. Would it still perform well at my mill’s capabilities at slower passes or smaller cuts? My max rpm is 2500 which is well below what people run a lot of the smaller carbide with. I know HSS is usually recommended but wasn't sure if there was a performance reason or just cost. Seeing as how i own all this carbide already cost isn't really the issue.

FYI MTM and Frankford Arsenal make some handle rifle ammo cases for a few bucks that fit endmills pretty well. Checkout my pictures. I can give you size/model recommendations if anyone is interested.

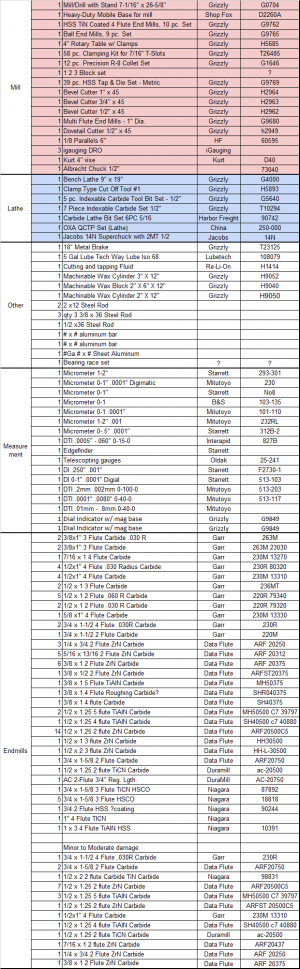

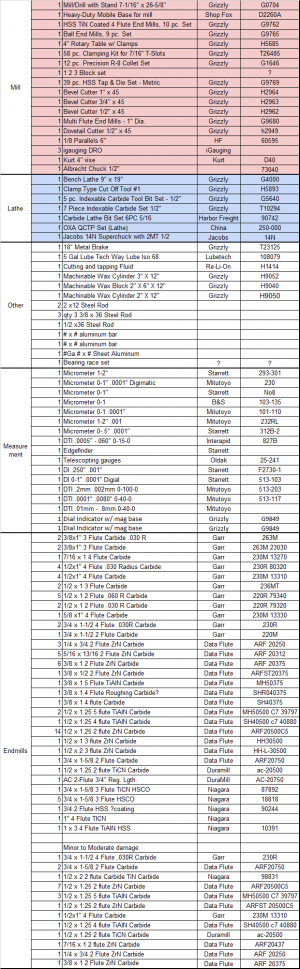

Here's a list of the items I have that either came with the purchase or I've picked up along the way. I scour ebay and want ads and pick up things on the thrift when I can. I try to get USA when it's reasonable but I'm not above import items.

Any hints for what i’m missing that would be useful in general would be great.

Open to recommendations but off the top of my head here are things I think I would find useful. Let me know if you think they are or not:

Also I can't imagine I'll ever need this many endmills so anyone is interested in some of the excess endmills I have I'd love to barter etc for some things I could use. Thanks for reading.

I have no particular projects in mind. Just hobbies or parts that could be useful in my regular putzing around in the shop or restoring old equipment. I’ll probably make a few upgrade parts for the machines first. I already added an OXO QCTP to the lathe and machined a female threaded bolt to interface with the existing stud. (Pictured). Potential next improvements:

- 4 Bolt clamp for Carriage on lathe

- iGuaging DRO install on Mill

- Maybe some kind of tramming apparatus for the mill

- I've seen a few people creatively mount some sort of adjustable DTI to the lathe to measure cuts quickly.

- Belt Drive Mill and maybe up spindle speed a hair

- Treadmill motor conversion for lathe

QCTP Machined female bolt (made from leftover suspension bolt because I dont throw anything out)

Fitment

I recently scooped up a endmill lot from a local guy. It's mainly carbide from Data Flute, Garr, Duramill, and Niagara. I’d say some of it looks new or still sharp, some used, and some a victim of poor storage and transport. I cleaned and lubed them up (although used an oiled rag which left some minor lint in the pictures). I’d wager some of the larger ones outsize my mill’s motor and rigidity. I know carbide is able to run a lot faster/harder in general at any size. Would it still perform well at my mill’s capabilities at slower passes or smaller cuts? My max rpm is 2500 which is well below what people run a lot of the smaller carbide with. I know HSS is usually recommended but wasn't sure if there was a performance reason or just cost. Seeing as how i own all this carbide already cost isn't really the issue.

FYI MTM and Frankford Arsenal make some handle rifle ammo cases for a few bucks that fit endmills pretty well. Checkout my pictures. I can give you size/model recommendations if anyone is interested.

Here's a list of the items I have that either came with the purchase or I've picked up along the way. I scour ebay and want ads and pick up things on the thrift when I can. I try to get USA when it's reasonable but I'm not above import items.

Any hints for what i’m missing that would be useful in general would be great.

Open to recommendations but off the top of my head here are things I think I would find useful. Let me know if you think they are or not:

- Flycutter

- Face mill

- Boring head and bars

- 115 Drill index

- Center drills

- Spotting drills

- HHS lathe bits or blanks

- Countersinks

- Deburring bits

Also I can't imagine I'll ever need this many endmills so anyone is interested in some of the excess endmills I have I'd love to barter etc for some things I could use. Thanks for reading.

Last edited: