- Joined

- Sep 29, 2017

- Messages

- 2,295

I am not sure yet how I am going to bill this apart from material price,so I am not sure if the profit will be enough so that buying a bender will be justified.

Why 40mm?I would cut a piece exactly 40mm long and put a bend in the center and measure each side to determine what is changing. At work we use a top die with a 094" radius. This will generally add one material thickness to each side of the corner.

Joe

Brino in my first post I think I mentioned thickness at 0.9mm stainless steel sheet and the internal length is 110mm with sides of 19mm from internal base to the top of the side.We need a bit more info to make any recommendations.

two more dimensions: sheet thickness, and length of bend.

material type will affect the strength of machine required

-brino

I do have a pneumatic hydraulic 10ton press.We need a bit more info to make any recommendations.

two more dimensions: sheet thickness, and length of bend.

material type will affect the strength of machine required

-brino

Pardon me,but is this a computer program?Draw it up in OnShape using the sheet metal feature, it'll tell you exactly where you need to be heading given your desired bend radius and K factor for the material.

Brino in my first post I think I mentioned thickness at 0.9mm stainless steel sheet and the internal length is 110mm with sides of 19mm from internal base to the top of the side.

You are apologizing too much my friend. No worries here.Sorry Michael it's my fault; I entirely missed the thickness and material you stated.

I need to slow down and read better.

But we're still missing the length (or is it width?) of the bend right?

(ie. do you need a 200mm brake or a 1000mm brake to do this.)

My apologies,

-brino

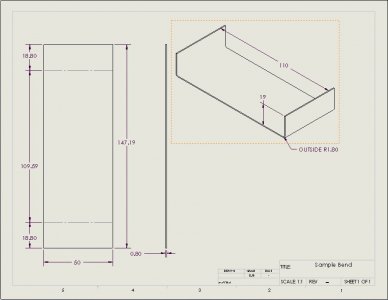

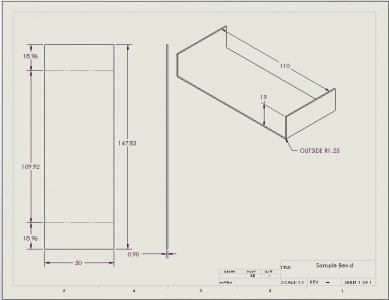

Thank you very nuch RJ for this, I realy appreciate it. O the width is also 19mm. Once again thank you.As to the original question about dimensions, here is a SolidWorks drawing reflecting the final dimensions and the flat sheet dimensions. I made some assumptions as to bend radius and width. but you get the idea.

Edit: I used .8mm instead of .9mm for the thickness on the drawing. The second drawing reflects a .9mm thickness and I also changed the inside bend radius to .25mm.View attachment 370168View attachment 370171