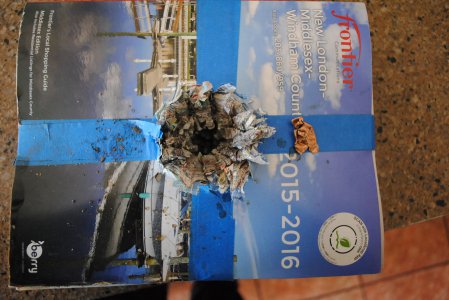

The epoxy bedding approach is often used to bed an action in the stock of a target rifle. It provides a 'stress free' joint, held together by two evenly torqued screws, that is very stable and solid.

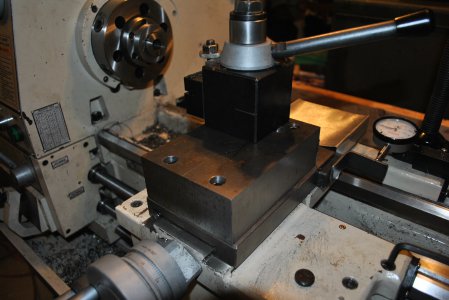

A ground plate may be flat, and the compound surface also, but both have tolerances. With cast iron you have to be extra careful about not stressing it (as you already know). To get a stress free fit they need to be lapped.

An alternative is epoxy bedding which would also provide a stress free mating surface on the plate. A very thin layer of epoxy would be permanently stuck to the plate only. This is accomplished by using a release agent on the surface of the compound so that the two parts can be separated after the epoxy has set without any epoxy being left on the compound. After that it would not be any more involved to install the plate on and off than before.

From one tinkerer to another, I have no milling work ahead to do. This is just an exercise for me. I sure am enjoying the exchange of ideas. I have already learned a lot about milling and hungry to know more.

Cheers everybody, Mike