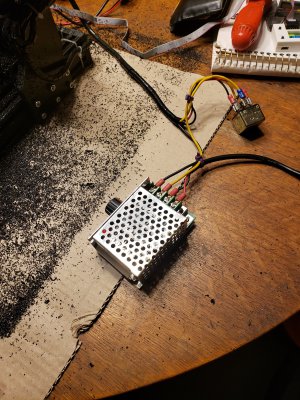

I have my power supply sorted out! Here's the deal, I got my new board yesterday, that fixed my spindle control problem (it would not turn off unless I pulled the plug). I got my new dc motor controller and stopped by work to get a 24v relay for a Volvo loader. I am now running a 20v power supply to run the board and the steppers. The board has a 12v side that I believe runs everything but the spindle, so I am confident that 20v is ok there. The original hi output 24v power supply is now dedicated to run the spindle, and power is switched with the 24v relay in the positive wire before the spindle. The relay is controlled by the original spindle power wires. I have run 3 parts so far, and it is working very well.

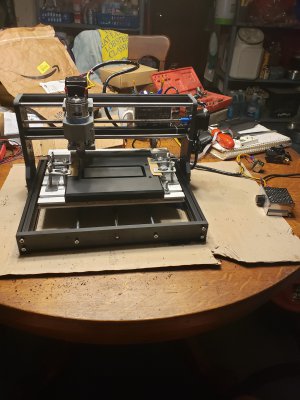

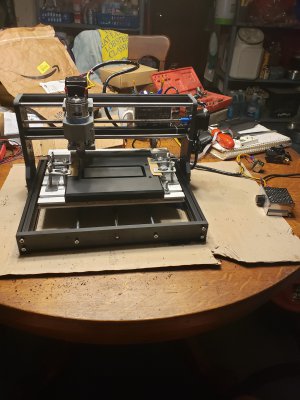

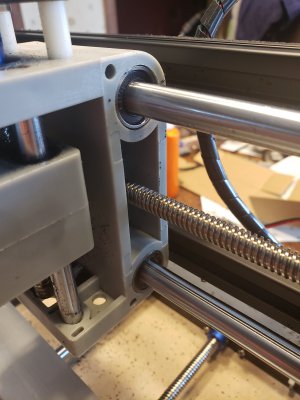

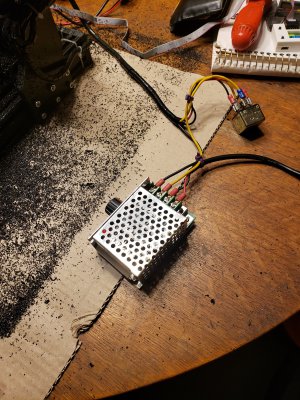

Here is what it it looks like.

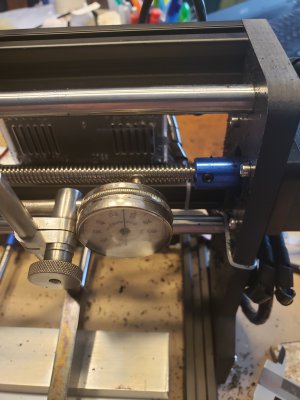

Also, I think that I mentioned that I was having a problem with swarf control and had to constantly be vacuuming while the router was running. This is what the 20,000rpm spindle and a larger 3 flute endmill did for me.

I only have to vacuum now to load a new part!

This is an entry level cnc router. I was pretty sure that it would do what I needed it to do for this job. You can only expect so much from a light machine like this (it's actually meant for engraving). We started with a 46 minute run time for each part. We got it down to 18 minutes, but bumped it back up to 22 minutes by decreasing the feed rate to prevent it from self destructing. I'm halfway way thru the 72 parts that I have to make. It seems like it will hold together so that I can get this job done.

Good little machine after a few upgrades!