I find all this odd since they advertise the 1236 and 1236T with BXA tooling and 5/8" shank toolsets and apparently in some cases, modification is necessary. Their XL or rather T version is what I got, just lowers the tool pocket by ~.06" compared to the regular sized ones. I figured modifying the tool holders as well if need be... there's always a way to fix things. I'd love to load up on the BXA tool holders from them... but hesitant until it's in front of me.I had a simular problem with my 12 x 37 lathe

I ordered the BXA holder with the 5 holders but the 5/8 tooling would not lower enough

The XL or T holders just fit with 5/8 tooling

The parting tool will not work without modifying the holder and turning the compound 90 degrees

I milled the holder to lower it below the compound

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I have on order a pm1236t and need some dimensions

- Thread starter myhreld

- Start date

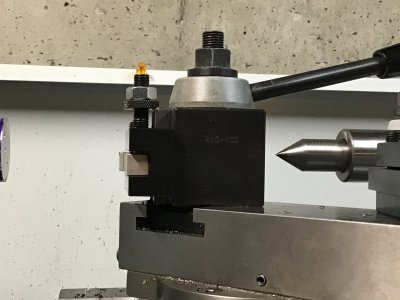

Here’s a picture of my Chinese knockoff AXA size toolpost with 1/2” tooling. There is still adjustment range if it needed to go up or down. 1/4” tools will fit as well, but I didn’t have any in toolholders to show. The tool post height is the same as an Aloris at 2.25”. It’s just shy of 1/4” below the toolholder to the compound.

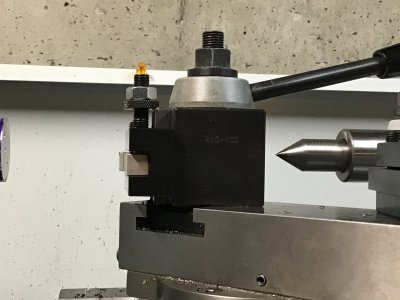

This picture is with the threading tool upside down, I want to try threading away from the chuck since I mostly do metric, it just barely is high enough without making a modification, so a BXA might be a better choice if you plan on doing this.

This picture is with the threading tool upside down, I want to try threading away from the chuck since I mostly do metric, it just barely is high enough without making a modification, so a BXA might be a better choice if you plan on doing this.

Thanks for the pics/illustrations. My Aloris BXA is 2.75" tall... that extra 1/2" compared to AXA would allow you to raise up your tool by that much without mod. I have seen some post/pics with a mod on the holder for times you need to go higher. I assume there's some practical limit, because you want the wedge/dovetail connection to have as much contact as possible.Here’s a picture of my Chinese knockoff AXA size toolpost with 1/2” tooling. There is still adjustment range if it needed to go up or down. 1/4” tools will fit as well, but I didn’t have any in toolholders to show. The tool post height is the same as an Aloris at 2.25”. It’s just shy of 1/4” below the toolholder to the compound.

View attachment 421584

This picture is with the threading tool upside down, I want to try threading away from the chuck since I mostly do metric, it just barely is high enough without making a modification, so a BXA might be a better choice if you plan on doing this.

View attachment 421585

Based on my calculations, 5/8" tooling in regular sized BXA tool holders bottomed out (bottom of BXA holder touching compound) should put the top of the shank (cutting insert, etc..) around ~1.125" above compound. That puts you ~.075" below center line, assuming compound to center line is 1.2", that's enough for some adjustability. So it seems the only reason to get the BXA XL/T holders to to lower that by .06"... it's not like you can get 3/4" tooling low enough, it'll be close if you can. This is all in context of the 1236T.

- Joined

- Dec 26, 2015

- Messages

- 2,139

We've been over this in DMs, but for others here, your assumption is that the cutting edge of the tool is at or below the top surface of the tool that's installed. While this is true of HSS and braised carbide tooling, it is not always the case with indexable tooling. Indexable parting tools, to pick one example, often position the cutting edge of the insert above the top surface of the tool holder. To run such a tool on a BXA with a CH of 1.200" would require modification of the tool shank or the QC tool holder to get the cutting edge positioned to the CL of the spindle. This is all documented in my book.Based on my calculations, 5/8" tooling in regular sized BXA tool holders bottomed out (bottom of BXA holder touching compound) should put the top of the shank (cutting insert, etc..) around ~1.125" above compound. That puts you ~.075" below center line, assuming compound to center line is 1.2", that's enough for some adjustability. So it seems the only reason to get the BXA XL/T holders to to lower that by .06"... it's not like you can get 3/4" tooling low enough, it'll be close if you can. This is all in context of the 1236T.

IMO, a Dorian QCTP would be ideal on the 1236T - it's 0.250" taller than the Aloris equivalent which positions it (height wise) between the Aloris AXA and Aloris BXA. That would provide plenty of adjustability of tool heights on that lathe, whereas the BXA really restructs the low-limit adjustability. Don't fool yourself into thinking 5/8" or 3/4" tooling is going to improve rigidity here - the compound itself is the spongy (flexible) aspect of these lathes, not the tool shank size.

Parting tools and all their various styles are certainly the outlier (in general) when it comes to where the cutting edge is in reference to the top of the shank. Parting blade height and how the holder positions it has everything to do with it. Some drop it quite a bit, some don't.your assumption is that the cutting edge of the tool is at or below the top surface of the tool that's installed. While this is true of HSS and braised carbide tooling, it is not always the case with indexable tooling. Indexable parting tools, to pick one example, often position the cutting edge of the insert above the top surface of the tool holder. To run such a tool on a BXA with a CH of 1.200" would require modification of the tool shank or the QC tool holder to get the cutting edge positioned to the CL of the spindle. This is all documented in my book.

I'm thinking of the most common indexable insert tool holders, at least to the "S" screw type. The cutting edge appears to be very close to the top of the shank... SCLCR, SCMCN, SSDCN, many others of different shapes, lay down threading with 16ER AG60 inserts, etc. I'm sure there are styles I'm not taking into consideration so I realize it's not an "always" or "never" scenario.

This is the part I don't get. As you suggest, something between the Aloris AXA and BXA size is likely a a better match for the PM1236T and that makes sense. However, in the case of the 1236T, it seems getting tool's cutting edge low enough is the real restriction because of the short 1.2" CH. At least for 5/8" shank tooling using BXA holders. Correct me if I'm wrong... no tool post, regardless of how short or tall it is, can get the QCTP tool holder (and the held tool) lower if it bottoms out on the compound the tool post is mounted to. Unless of course, you can drop the QCTP tool holder below the top of the compound OR you lower the bottom edge of the QCTP tool holder's pocket. Both of those likely require modification.IMO, a Dorian QCTP would be ideal on the 1236T - it's 0.250" taller than the Aloris equivalent which positions it (height wise) between the Aloris AXA and Aloris BXA. That would provide plenty of adjustability of tool heights on that lathe, whereas the BXA really restructs the low-limit adjustability

Given PM (for better or worse) pairs the 1236T with Aloris sized BXA tool post and 5/8" tooling you are required to nearly bottom out your QCTP holders, nearly resting on the compound. Nothing wrong with that, just an analysis of where it's going to be adjusted on the PM1236T. As long as your height adjustment screw gets you to the bottom, you are good to go (and your tools proper cutting height is achieved). Or just pick 1/2" tooling, you've now shortened your cutting height by .125".

The seemingly short 1.2" CH on the 1236T (but what do I know) is most concerning when it comes to parting blades when they are not significantly lowered in the holder like the Aloris #71. Though on the Aloris #71, you may run into compound interference. As we've discussed, the Aloris #77 has a shorter blade but the cutting height is actually higher because they don't drop the blade down like on the Aloris #71.

Understood. My point was not about rigidity. My point was that if you are getting PM's BXA XL / T tool holders to use 3/4" tools on the PM-1236T it seems like a useless endeavor because you probably can't get the cutting height of a 3/4" low enough regardless of what size QCTP you have. And if you get them just for 5/8" tooling, it only lowers the pocket by .06" (which is different if you do the math based on their advertised dimensions). Of course, if .06" lower is what you need, you are golden. Having lots of extra adjustability, high or low, doesn't do anything for you either (for a given tool).Don't fool yourself into thinking 5/8" or 3/4" tooling is going to improve rigidity here - the compound itself is the spongy (flexible) aspect of these lathes, not the tool shank size.

Having a larger range is preferred so you are less likely to run into adjustment issues for more tooling.

Obviously, modifying any part, the QCTP tool holder, the shank, replacing the compound with a fixed block of a different height can all do the trick as well. I hope that's not necessary right out of the box.

In my estimation, I've landed on this basic formula to determine if tooling will fit without modification....

And from Dorian's docs, a good illustration/formula. From this doc : https://www.doriantool.com/wp-content/uploads/SEC-B-TOOL-POST-TOOLHOLDERS-2016.pdf

Last edited:

The only time I have wanted extra height is for the upside down threading tool, but I imagine another situation may arise in the future where that could be handy. I definitely do not want 3/4” tools for my lathe, even 5/8” seems overkill in many situations, but there are more options that could help that makes BXA attractive. I haven’t run out of room either above or below the tool holder with any of my tools, except for upside down threading.Thanks for the pics/illustrations. My Aloris BXA is 2.75" tall... that extra 1/2" compared to AXA would allow you to raise up your tool by that much without mod. I have seen some post/pics with a mod on the holder for times you need to go higher. I assume there's some practical limit, because you want the wedge/dovetail connection to have as much contact as possible.

Based on my calculations, 5/8" tooling in regular sized BXA tool holders bottomed out (bottom of BXA holder touching compound) should put the top of the shank (cutting insert, etc..) around ~1.125" above compound. That puts you ~.075" below center line, assuming compound to center line is 1.2", that's enough for some adjustability. So it seems the only reason to get the BXA XL/T holders to to lower that by .06"... it's not like you can get 3/4" tooling low enough, it'll be close if you can. This is all in context of the 1236T.

I saw that when I was looking at possibly upgrading my AXA toolpost, but then forgot about that when I went down the Multifix rabbit hole, thanks for the reminder.IMO, a Dorian QCTP would be ideal on the 1236T - it's 0.250" taller than the Aloris equivalent which positions it (height wise) between the Aloris AXA and Aloris BXA.

Have you taken a look at the Aloris #8 HSS threading holder? By positioning the blade on the top (not like it's pictured) you can thread in reverse (I assume that's upside down as you call it) and away from the chuck. These have nearly zero reviews/demos on the web, seem like a good option though. These even hold laydown heads for holding your standard 16ER AG60 carbide inserts. Don't look at their #88 holder, it's crazy expensive and this one will do everything it can... just doesn't have the cool angle markings for the helix angle.The only time I have wanted extra height is for the upside down threading tool,

Yea, figured, I was calling that out just for analysis if anything. I really have now clueI definitely do not want 3/4” tools for my lathe, even 5/8” seems overkill in many situations

- Joined

- Dec 26, 2015

- Messages

- 2,139

You can move the QCTP off center of the compound and create the clearance necessary to drop a QC tool holder below the compound top surface. I don't recommend doing that because it will significantly lower the rigidity of the setup. If you use a solid tool post, you can also set that up in such a way to position QC tool holders below what would have been the top surface of the compound. What's ideal here is to maximize the surface contact between the QCTP and the QC tool holder at the dovetail interfaces.This is the part I don't get. As you suggest, something between the Aloris AXA and BXA size is likely a a better match for the PM1236T and that makes sense. However, in the case of the 1236T, it seems getting tool's cutting edge low enough is the real restriction because of the short 1.2" CH. At least for 5/8" shank tooling using BXA holders. Correct me if I'm wrong... no tool post, regardless of how short or tall it is, can get the QCTP tool holder (and the held tool) lower if it bottoms out on the compound the tool post is mounted to. Unless of course, you can drop the QCTP tool holder below the top of the compound OR you lower the bottom edge of the QCTP tool holder's pocket. Both of those likely require modification.

My point about the BXA on a 1236T is that the top surface of most tools when fully lowered is shockingly close to the CL of the spindle. I would want more margin than 0.070". An AXA will lower to 0.900" which is 0.200" lower than the 1236T spindle CL, and with the Dorian AXA you can elevate the top of the tool to 2.00" above the compound top surface, giving you a full 1.100" of vertical positioning flexibility while maintaining full dovetail contact between the QCTP and the QC tool holder.

I have already done all the math on this, drawn up detailed to-scale 3D models of all the combinations and permutations of AXA, BXA, CXA and the associated nominal and XL QC tool holders. It's all laid out on page 96 of my book which I know you already have. I stand by my recommendation of the Dorian AXA to give maximum tool positioning flexibility on the 1236T. Will a BXA work? Yes, but it doesn't leave you much wiggle room for setting proper tool heights, and could be problematic with many available parting tools. Haven't we beat this horse to death?In my estimation, I've landed on this basic formula to determine if tooling will fit without modification....

View attachment 421631

And from Dorian's docs, a good illustration/formula. From this doc : https://www.doriantool.com/wp-content/uploads/SEC-B-TOOL-POST-TOOLHOLDERS-2016.pdf

View attachment 421635

I've seen that holder before, looks like a neat idea. I didn't realize you could change the orientation of the blade, that could be a possibility. I already have an on edge insert threading tool, so I will probably use that for now. David's comment about the Dorian tool post got me interested again in considering that option. However, I noticed Dorian does not list it on their website any longer, so not sure how much longer that will be available.Have you taken a look at the Aloris #8 HSS threading holder? By positioning the blade on the top (not like it's pictured) you can thread in reverse (I assume that's upside down as you call it) and away from the chuck. These have nearly zero reviews/demos on the web, seem like a good option though. These even hold laydown heads for holding your standard 16ER AG60 carbide inserts. Don't look at their #88 holder, it's crazy expensive and this one will do everything it can... just doesn't have the cool angle markings for the helix angle.

View attachment 421638

Yea, figured, I was calling that out just for analysis if anything. I really have now clue, learning (aka, spending) as I go. I just went with.. "PM pairs 1236T with BXA and 5/8" tooling so that must be a good matchup... so I'm running with it...... man, I hope I don't regret all this "getting started tooling" I'm buying before I actually have the lathe.

The Quadra tool post they are offering now looks to be a nice alternative to a Multifix, but that is a significant increase in price over a standard style.

Yea, just taking me longer for all that to sink in and the real world affects.My point about the BXA on a 1236T is that the top surface of most tools when fully lowered is shockingly close to the CL of the spindle. I would want more margin than 0.070".

Totally see the light of day on that recommendation. Since I already sourced the Aloris BXA, the easiest thing to do is use 1/2" tooling if I need to, that gives back another .125" adjustability on the bottom end and in combination of the XL/T I'm near the full adjustability of the Dorian AXA setup, even more on the top end. Or, I'll modify my tool holders (another reason to add a mill to my shop) The challenge with static illustrations and such is that they can't represent all possibilities in one snapshot and there are few variables at play. I had a naïve understanding that I "should" be using 5/8" tooling with a BXA tool post and was wondering why PM didn't pair the 1236T with an AXA. Clearly, there's no mandate or absolute right/wrong setup... I just dig in and go over this, and over, and over... even drives me nuts. Not intentionally beating this dead horse, just my OCD'ness taking over.I stand by my recommendation of the Dorian AXA to give maximum tool positioning flexibility on the 1236T. Will a BXA work? Yes, but it doesn't leave you much wiggle room for setting proper tool heights,