- Joined

- Jun 20, 2022

- Messages

- 235

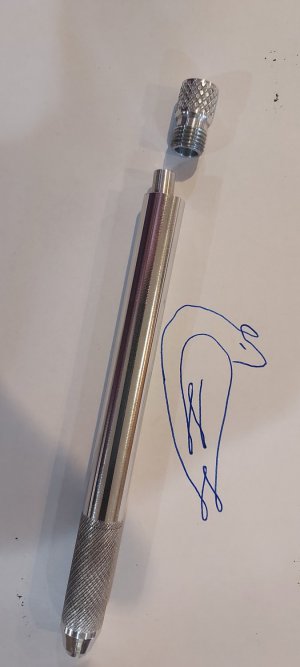

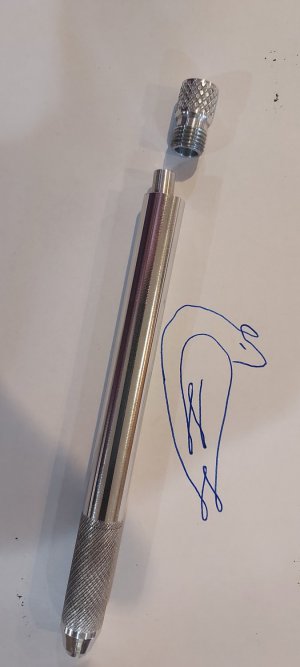

Thoughts on how to tighten threads? Made a pen with a screw in plunger to extend the ball point. Problem is I had to remake parts several times due to breakage at threaded areas, so I sized then a few thou loose to make tap and die work easier. Now I see I will probably loose this "nub" because it will work itself loose when not under tension (ball point retracted).

I thought maybe turn an inverted cone and try to squeeze it but I don't know if AL is malleable enough to do that....

Yes I screwed up the knurl too. Live and learn.

I thought maybe turn an inverted cone and try to squeeze it but I don't know if AL is malleable enough to do that....

Yes I screwed up the knurl too. Live and learn.