- Joined

- Nov 28, 2013

- Messages

- 197

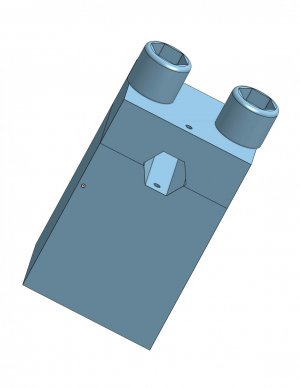

This is a jig for drilling transverse holes in brass stand-offs, the kind that are used to stack pcb boards in electronic devices. They are hexagonal and the ones I'm using have sides which are 0.100 inch across the face. My plan was to mill to the depth that the flat needs to be in both parts, then use a 60 Degree chamfer bit to cut the angle. The 60 degree bits I see on-line all have very sharp points and I wonder if one of these will cut all the way to the flat. I suppose I could grind the nose flat to get rid of the point, but do you think I need to. Material will be 6061 T6 - mostly because I have a lot of that around.

FWIW, the model was made with OnShape which is a cloud solid modeling CAD application which is free so long as you are comfortable with your work being accessible to all of their users. I love it.

FWIW, the model was made with OnShape which is a cloud solid modeling CAD application which is free so long as you are comfortable with your work being accessible to all of their users. I love it.