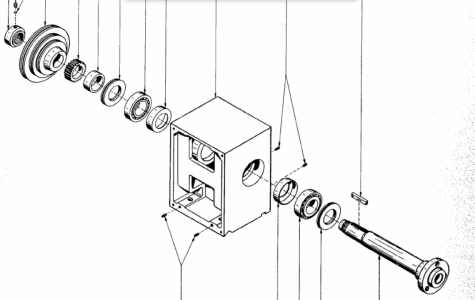

Preload is the amount of load placed on the bearings to reduce the amount of play in the spindle. This lets the spindle run true with minimum deflection under load. When preload is too tight, the bearings can overheat and seize. If the preload is too little, you get excessive deflection of the spindle, but you also reduce the natural frequency of the spindle system. Lets say for example with proper preload the natural frequency of the spindle is 3,000 rpm, if the preload is too loose, that could drop into your operating range.

The right amount of preload in these machines is a bit of art, you need to adjust and test. If it is difficult to turn the shaft by hand, preload is too high, you should be able to spin the chuck and get a few rotations before it stops. When you run the machine up to speed for a while, it should get a bit warm. If it is too hot to touch, too much preload. If you decide to try adjusting the preload, make a mark on the preload nut and spindle so you know where you started so that if you wanted to go back to that setting, it is easy to do.

The right amount of preload in these machines is a bit of art, you need to adjust and test. If it is difficult to turn the shaft by hand, preload is too high, you should be able to spin the chuck and get a few rotations before it stops. When you run the machine up to speed for a while, it should get a bit warm. If it is too hot to touch, too much preload. If you decide to try adjusting the preload, make a mark on the preload nut and spindle so you know where you started so that if you wanted to go back to that setting, it is easy to do.