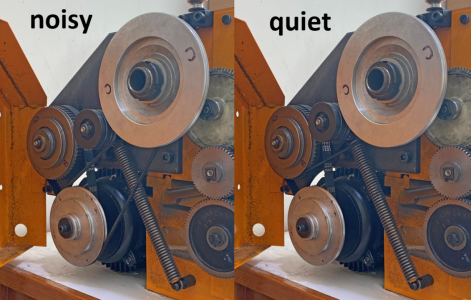

It's my EMCO Compact 8. The noise level is very acceptable at 500 rpm but then it would step up to max at 850 rpm and then reduced by a bit at 1700 rpm. Obviously some kind of resonance is happening. May I have some suggestions on how to cut the noise down at 850 rpm ? Thanks in advance and Merry Christmas

Last edited: