- Joined

- Nov 24, 2014

- Messages

- 3,594

Jon has written that your lathe has a MT3 spindle taper. Based on that info, I recommend that you buy an ER40 Collet Chuck w/ integral MT3 shank threaded for a draw bar (not w/ a tang).

Here is a link to one example; http://www.ebay.com/itm/NEW-M12-MT3...hash=item415dbfb2a4:m:m7ACuA3wJL7sZUJYdWx4ZZw

I don't know anything about the quality, precision or seller of the linked item and just offer it as an example of the "type" recommended.

I recommend the shank that is tapped for a drawbar so that you can make one up out of a long bolt or all-thread and rest assured that the chuck is positively retained in the spindle. To remove the chuck, loosen the drawbar a couple of turns and rap the end (nut protecting the threads) to dislodge the mating tapers.

I recommend the ER40 type because of it's larger capacity. Plan ahead. As you build your capability, through increased knowledge, experience and tooling, projects will present themselves that you haven't foreseen. Even though the project that you have in mind (Spitfire) needs 8mm max, 40mm capability will come in handy before long. If the ER40 is uncomfortably large for your model work, buy it anyway. You can also buy an ER16 stub chuck and hold it in the ER40.

ER16 short straight shank example; http://www.ebay.com/itm/New-C1-ER16...664036?hash=item4173711124:g:hhUAAOxy4fVTACYB

Your collection of collets can be built piece by piece, as projects require, or in a complete set, if budget allows.

Be aware of the precision of the tooling that you buy. If TIR (Total Indicator Reading or Total Indicated Runout, same meaning) is not specified (guaranteed) be skeptical and ask. If they don't know or don't reply, IMO they are not likely to replace an unacceptable item (what warranty?). After you get your tooling, measure TIR to verify it's as expected. Only buy hardened and ground collet chucks, arbors and collets as they will give long service under any reasonable circumstances.

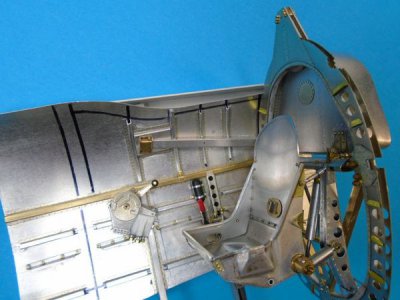

Please consider starting a thread, with pics of course, about your Spitfire build. Sounds like fun.

Here is a link to one example; http://www.ebay.com/itm/NEW-M12-MT3...hash=item415dbfb2a4:m:m7ACuA3wJL7sZUJYdWx4ZZw

I don't know anything about the quality, precision or seller of the linked item and just offer it as an example of the "type" recommended.

I recommend the shank that is tapped for a drawbar so that you can make one up out of a long bolt or all-thread and rest assured that the chuck is positively retained in the spindle. To remove the chuck, loosen the drawbar a couple of turns and rap the end (nut protecting the threads) to dislodge the mating tapers.

I recommend the ER40 type because of it's larger capacity. Plan ahead. As you build your capability, through increased knowledge, experience and tooling, projects will present themselves that you haven't foreseen. Even though the project that you have in mind (Spitfire) needs 8mm max, 40mm capability will come in handy before long. If the ER40 is uncomfortably large for your model work, buy it anyway. You can also buy an ER16 stub chuck and hold it in the ER40.

ER16 short straight shank example; http://www.ebay.com/itm/New-C1-ER16...664036?hash=item4173711124:g:hhUAAOxy4fVTACYB

Your collection of collets can be built piece by piece, as projects require, or in a complete set, if budget allows.

Be aware of the precision of the tooling that you buy. If TIR (Total Indicator Reading or Total Indicated Runout, same meaning) is not specified (guaranteed) be skeptical and ask. If they don't know or don't reply, IMO they are not likely to replace an unacceptable item (what warranty?). After you get your tooling, measure TIR to verify it's as expected. Only buy hardened and ground collet chucks, arbors and collets as they will give long service under any reasonable circumstances.

Please consider starting a thread, with pics of course, about your Spitfire build. Sounds like fun.