- Joined

- Feb 13, 2017

- Messages

- 2,138

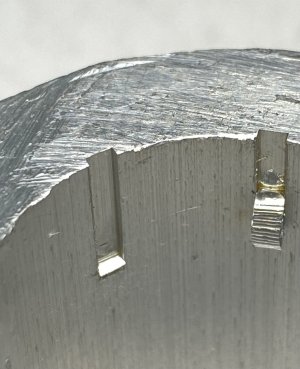

That's what the sacraficial slugs were for.Several approaches to work around this.

Drilling, or plunging with an endmill into full material (not on an edge) balances the sideways load on the endmill so it is purely twisting. Actually any plunge that is symmetric around the center of the endmill will be pure torque. Taking smaller cut steps would reduce the sideways force. Another way to do this is to use a 2 mm endmill and cut the right (clockwise) edge in steps, then shift over counterclockwise by .5 mm and cut again, being careful to cut no deeper than the first pass.

.