- Joined

- Oct 16, 2019

- Messages

- 6,877

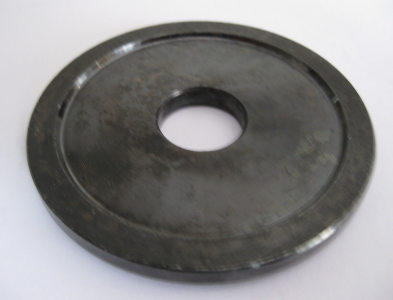

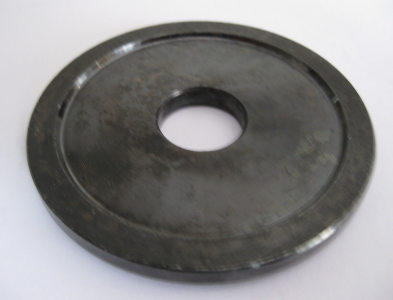

The washer that goes next to the blade on my Unisaw is pooched. Years of use have taken all of the dish out of it and it no longer spreads the clamping load evenly. I found one on eBay but it will be about $50 CDN to get it here.

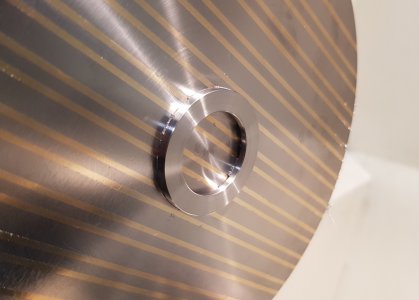

Dimensions are 2.25" diameter, 5/8" bore, total thickness is .25 though thicker is not an issue.

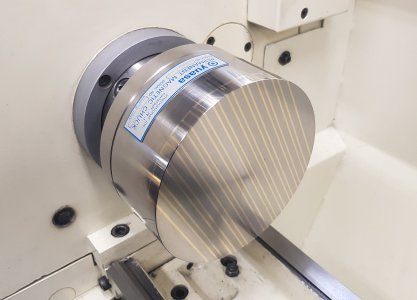

My thoughts are to chuck up a length of 2.25+ stock and turn the diameter and the features on the flat side, then take it out, bandsaw it off slightly thicker than .25 put it in the 4-jaw, center it, bore the hole and turn the shallow taper.

My concern is grip on the edge which might be an 1/8"

One other though is to bore it and then put it on a mandrel. Parallelism of the flat side to the small flat on the tapered side is the most important aspect not concentricity of the bore to the outside diameter.

This is what I want to make

Dimensions are 2.25" diameter, 5/8" bore, total thickness is .25 though thicker is not an issue.

My thoughts are to chuck up a length of 2.25+ stock and turn the diameter and the features on the flat side, then take it out, bandsaw it off slightly thicker than .25 put it in the 4-jaw, center it, bore the hole and turn the shallow taper.

My concern is grip on the edge which might be an 1/8"

One other though is to bore it and then put it on a mandrel. Parallelism of the flat side to the small flat on the tapered side is the most important aspect not concentricity of the bore to the outside diameter.

This is what I want to make