- Joined

- Nov 8, 2020

- Messages

- 46

Hey everyone,

So I'm owner of a lathe for maybe 1 month now and I'm still getting used to using it. I now have to turn a small disk and I am scratching my head on how to dial that part in...

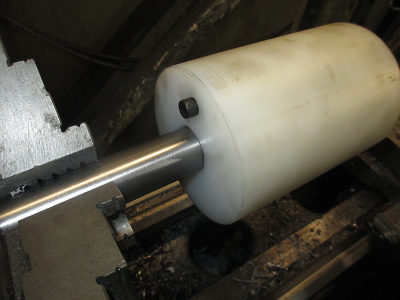

So the disc is 4mm (0,15") thick and 90mm (3,5") in diameter, I turned the outside diameter by putting the disc on an arbor. I now wish to bore out the center and only my 4-jaw has a wide enough opening to hold that part, so I have to dial it in... but how?

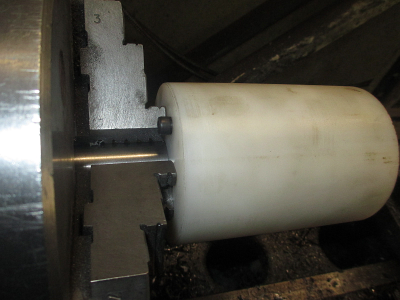

The problem is, that the part doesn't protrude the jaws so there is no way to reach the outside diameter with an indicator and then turn the chuck. I also can't shim the part so it protrudes the chuck slightly because there would maybe be 1-2mm (0,04"-0,08") of part to grip to left.

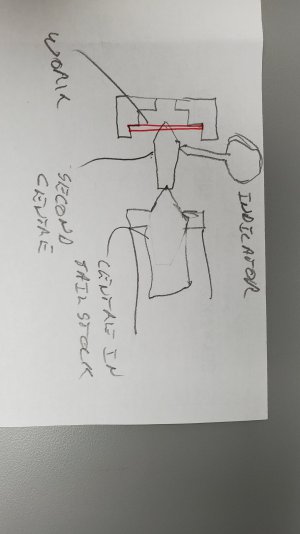

Another possibility would be to dial in at the bore with a dial test indicator. Bu then again the bore is only 10mm (0,4") and rough drilled so I don't know how accurate that would be. Any suggestions?

So I'm owner of a lathe for maybe 1 month now and I'm still getting used to using it. I now have to turn a small disk and I am scratching my head on how to dial that part in...

So the disc is 4mm (0,15") thick and 90mm (3,5") in diameter, I turned the outside diameter by putting the disc on an arbor. I now wish to bore out the center and only my 4-jaw has a wide enough opening to hold that part, so I have to dial it in... but how?

The problem is, that the part doesn't protrude the jaws so there is no way to reach the outside diameter with an indicator and then turn the chuck. I also can't shim the part so it protrudes the chuck slightly because there would maybe be 1-2mm (0,04"-0,08") of part to grip to left.

Another possibility would be to dial in at the bore with a dial test indicator. Bu then again the bore is only 10mm (0,4") and rough drilled so I don't know how accurate that would be. Any suggestions?