-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

how much bigger does a drill bit drill?

- Thread starter Rcdizy

- Start date

- Joined

- Nov 23, 2014

- Messages

- 2,634

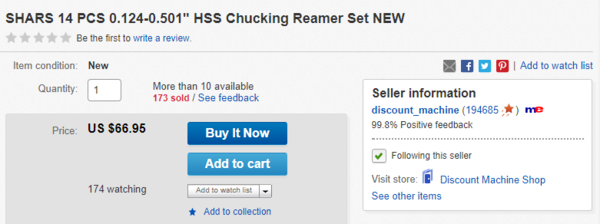

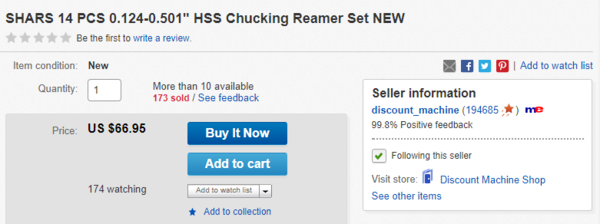

Like mentioned above (so not adding any help here), I'd spot drill for starters, then drill undersized by 0.010" - 0.015". Then use an undersized or oversized (+/- 0.001" from 3/16") ream. The oversize will give you a slip fit for separating the parts. I've had very good success with my over/under set from Shars off eBay for a touch over $70 delivered. The set includes reams from 1/8" - 1/2" by 1/16", probably the only reams you'll ever use.

Bruce

Bruce

- Joined

- Jul 2, 2014

- Messages

- 7,594

Internal cuts are more difficult to hit accurately than external cuts. They can be more difficult to measure accurately and the tooling is much less rigid, at least for small holes. They are of course totally doable.I just turned a shank for a tool I'm making on my sherline lathe to .3750 on the dot, over the entire length of the shank... seeing as how boring is exactly the same operation im going to go ahead and say that you could in fact get the press fit right...

- Joined

- Apr 27, 2017

- Messages

- 122

Given that the smallest cut you can take is directly proportional to the surface finish of your cutting tool (I took mine to a mirror finish for the last cut on that shank which was 0.007mm or about 0.00027 inch) the largest factor in how well you can finish a part out is machine repeat-ability, with a highly polished cutting tool you can take multiple 'spring passes' to virtually eliminate any deviations in diameter caused by a lack of tool rigidity. I'm learning that working on a small lathe on small parts is entirely different than forcing your way through material on a large heavy rigid lathe using rigid tools... I honestly didn't know what to do when I got my sherline, started cutting and realized just how floppy everything was... I don't have anything to accurately measure an run-out on an ID so I can't compare but I have bored small holes in watch parts using tools that I ground and polished on my faceting machine and the holes preformed as designed.

- Joined

- Jul 2, 2014

- Messages

- 7,594

I don't see what "polish" has to do with it. If you are speaking of honing the cutting edge, then yes, a sharp tool deflects less. The amount of shininess has little to do with it. At some point, mirror polishing will make the edge less sharp, and sharp is what is needed. A shiny and dull tool will just rub.Given that the smallest cut you can take is directly proportional to the surface finish of your cutting tool (I took mine to a mirror finish for the last cut on that shank which was 0.007mm or about 0.00027 inch) the largest factor in how well you can finish a part out is machine repeat-ability, with a highly polished cutting tool you can take multiple 'spring passes' to virtually eliminate any deviations in diameter caused by a lack of tool rigidity. I'm learning that working on a small lathe on small parts is entirely different than forcing your way through material on a large heavy rigid lathe using rigid tools... I honestly didn't know what to do when I got my sherline, started cutting and realized just how floppy everything was... I don't have anything to accurately measure an run-out on an ID so I can't compare but I have bored small holes in watch parts using tools that I ground and polished on my faceting machine and the holes preformed as designed.

- Joined

- Apr 27, 2017

- Messages

- 122

polishing and honing describe an almost identical process, the use of abrasive to produce a precision surface. Polishing is typically only about making something shiny, and also typically to tighter surface tolerance. But in gem cutting which is my default when talking about making precision surfaces, polishing is about surface finish (100k - 200k grit typical) AND producing that finish on a very sharp edge consisting of two or more very very flat planes. I've been cut by many a sapphire... So I agree with you that typical polishing won't produce a cutting tool and instead a rubomax, but if done correctly you can get an incredibly sharp cutter that will cut shallow with no problem... you just can't take a deep cut with it or you ruin all your hard work...

- Joined

- Feb 1, 2015

- Messages

- 9,986

A lot of information is missing here. Is the a hole in the end of a piece of round, in a flat plate, or in an irregularly shaped part. What is the machine; lathe, mill, drill press? What class of fit? How deep is the desired hole? There is a big difference on boring a 1/8" deep hole through a piece of plate and boring a 1" deep hole.

As to boring and turning being equivalent operations, I would say only on the condition that you were boring a fairly shallow hole. For a hole where the depth greatly exceeds the diameter, the boring bar will be relatively flexible and subject to deflection. Measuring the diameter of a hole is problematic as well. A pin gage will only tell you what the smallest diameter is. It conveys no information regarding roundness, cylindricity, surface finish, etc. Determining the true state of a hole requires the use of something like an air gage.

As to boring and turning being equivalent operations, I would say only on the condition that you were boring a fairly shallow hole. For a hole where the depth greatly exceeds the diameter, the boring bar will be relatively flexible and subject to deflection. Measuring the diameter of a hole is problematic as well. A pin gage will only tell you what the smallest diameter is. It conveys no information regarding roundness, cylindricity, surface finish, etc. Determining the true state of a hole requires the use of something like an air gage.

- Joined

- Jul 2, 2014

- Messages

- 7,594

The first thing that comes to my mind with polishing is a buffing wheel on a motor shaft and a stick of rouge. That is not going to make something sharp, just shiny. Thanks for the clarification of what you meant and how you achieve it.polishing and honing describe an almost identical process, the use of abrasive to produce a precision surface. Polishing is typically only about making something shiny, and also typically to tighter surface tolerance. But in gem cutting which is my default when talking about making precision surfaces, polishing is about surface finish (100k - 200k grit typical) AND producing that finish on a very sharp edge consisting of two or more very very flat planes. I've been cut by many a sapphire... So I agree with you that typical polishing won't produce a cutting tool and instead a rubomax, but if done correctly you can get an incredibly sharp cutter that will cut shallow with no problem... you just can't take a deep cut with it or you ruin all your hard work...

- Joined

- Jun 7, 2013

- Messages

- 10,450

I quite agree with the earlier writer who suggests the over/under reamers; I had a set at my shop (left them there) and every time I used them to fit holes for dowel pins, they made the proper fits; force fit for the part the pin is pushed into, and a snug fit for the other part. Drills have no place in this sort of work, other than to make a hole for the reamer to enlarge.

- Joined

- Jul 2, 2014

- Messages

- 7,594

I have lots of nice previously owned reamers from many sources, and usually have the one I need for a job, but it can take time to find it. They are sorted by nominal size, but many are really difficult to read, and I never know if they have been previously sharpened, so I have to measure or test them, and also pick one the right style for the hole type as well. Sometimes have to hone it sharp, too. That all takes time, lots of it. I have to admit that a set of over/under reamers in basic fractional sizes like Bruce posted sure sounds quick and easy for lots of work.I quite agree with the earlier writer who suggests the over/under reamers;