This must have been answered multiple times before..my apologies and I will happily read any pointer to earlier threads...

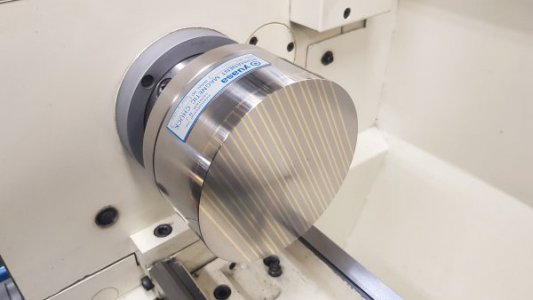

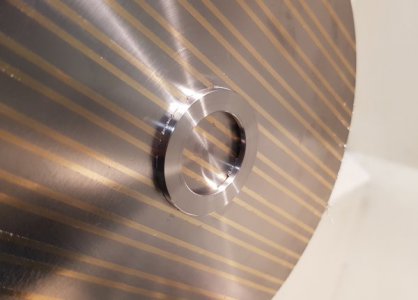

I have a 7” steel disk (I don’t know what kind of steel, but it is magnetic and I can mill it with a carbide end mill). It is a wedge going from .3” to .4”

I want to turn it down to a uniform .3” on my PM1030V. I have a backplate. I do not want a center hole in the disk. I want all three sides machined.

How do I mount it to the back plate? Or, do I glue it to a short cylinder (co-axial with great care) that I then grab in a chuck? What glue is strong enough but also can release? This will be an interrupted cut.

Work holding is always such a puzzle.

Thank you for any ideas.

Cordially,

Bill

I have a 7” steel disk (I don’t know what kind of steel, but it is magnetic and I can mill it with a carbide end mill). It is a wedge going from .3” to .4”

I want to turn it down to a uniform .3” on my PM1030V. I have a backplate. I do not want a center hole in the disk. I want all three sides machined.

How do I mount it to the back plate? Or, do I glue it to a short cylinder (co-axial with great care) that I then grab in a chuck? What glue is strong enough but also can release? This will be an interrupted cut.

Work holding is always such a puzzle.

Thank you for any ideas.

Cordially,

Bill