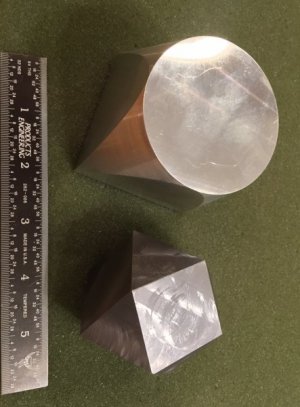

As suggested make 3 sides on end of round stock.

depends on what machines are available but the last cut is the critical one.

Our suggestion is as follows.

Get the round stock with 3 sides finished in the lathe in a 4 jaw so it can be dead nuts centered and true.

Get some sacrificial material such as PVC that the part will fit in.

First clean part with acetone then coat it with a thin brushed on ) layer of epoxy.

Give it another coat to insure no surface not covered.

Mix some bondo and fill the PVC and place it over the part and get it to run true as possible.

Let it cure fully and place a PVC cap on end and face it then center drill it.

Now make tiny cuts to get the PVC to run true.

Now use cutoff tool to remove part.

Hold by PVC and take tiny cuts until you get the correct face.

Finish polish then toss it in the freezer.

The part should break loose.

The epoxy usually will break off of a polished surface and can be cleaned up where the bondo will not let go and will be difficult to remove.

depends on what machines are available but the last cut is the critical one.

Our suggestion is as follows.

Get the round stock with 3 sides finished in the lathe in a 4 jaw so it can be dead nuts centered and true.

Get some sacrificial material such as PVC that the part will fit in.

First clean part with acetone then coat it with a thin brushed on ) layer of epoxy.

Give it another coat to insure no surface not covered.

Mix some bondo and fill the PVC and place it over the part and get it to run true as possible.

Let it cure fully and place a PVC cap on end and face it then center drill it.

Now make tiny cuts to get the PVC to run true.

Now use cutoff tool to remove part.

Hold by PVC and take tiny cuts until you get the correct face.

Finish polish then toss it in the freezer.

The part should break loose.

The epoxy usually will break off of a polished surface and can be cleaned up where the bondo will not let go and will be difficult to remove.