- Joined

- Nov 24, 2013

- Messages

- 268

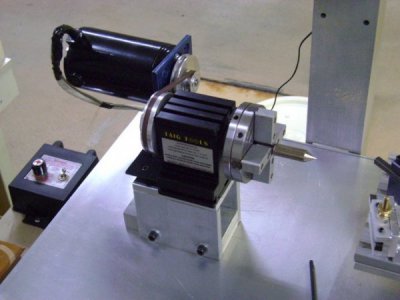

This is the first time I tried to use the Taig 4 jaws chuck but the center tool I have mounted wobbles a bit. If I remember this chuck was described as self centering but it’s very awkward to turn the chuck plates to secure a tool. Is there a procedure to use this chuck the first time?

And what is the purpose of the 2 holes on the exterior face of each jaw?

Nicolas

And what is the purpose of the 2 holes on the exterior face of each jaw?

Nicolas