- Joined

- Sep 22, 2010

- Messages

- 7,222

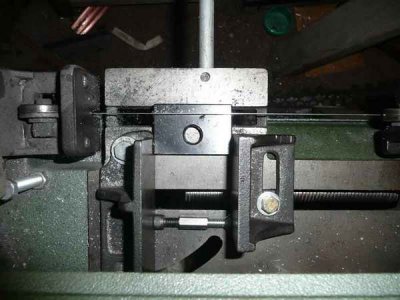

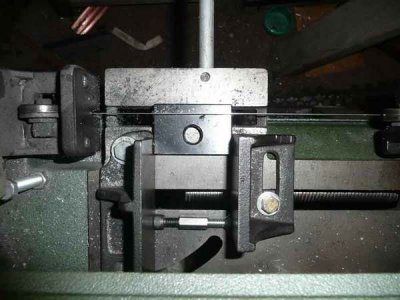

You buy a new QCTP and it comes with an oversize "T" nut that you have to mill to size.

How do you do it? (Photos if possible). How do you measure the correct dimensions of the T-slots, set up the job on the milling machine or other machine that you use, and remove the excess material.

This is an important task for newbies.

Thanks,

Nelson

How do you do it? (Photos if possible). How do you measure the correct dimensions of the T-slots, set up the job on the milling machine or other machine that you use, and remove the excess material.

This is an important task for newbies.

Thanks,

Nelson

![teenut3[1].jpg teenut3[1].jpg](https://www.hobby-machinist.com/data/attachments/0/885-da52e6071eeee82ce135f3c53f4229db.jpg)

![teenut2[1].jpg teenut2[1].jpg](https://www.hobby-machinist.com/data/attachments/0/916-fcaeb413454e639484ec25a10a397960.jpg)