I used a die to thread a rod and the resultant threads were not square. When the rod is threaded into a Tee nut with square threads it rotates. Regular bolts thread without rotating.

How can a die be used to cut threads that are square?

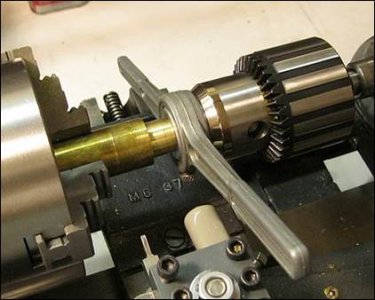

Is the best way to do this by cutting threads in a lathe?

How can a die be used to cut threads that are square?

Is the best way to do this by cutting threads in a lathe?