- Joined

- Nov 26, 2012

- Messages

- 1,307

Other than general durability will hardened drill rod make for a more ridged boring bar than normalized rod? If the Young's modulus doesn't change with hardening wouldn't that mean the stiffness would remain the same? Sorry but everything I learn is from reading so I might have that all messed up.

Cheers

Shawn

I'm at a loss to find understandable answers to that. I was told that in the past and didn't bother with tool steel because of it.

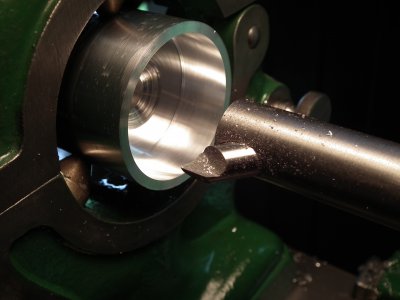

I was making my boring bars from 1144 stressproof. When I did make one out of 0-1 drill rod that I hardened and tempered , It seemed to work much better and seemed stiffer. Maybe its all psychological. I put more work into it it's gotta be better "right"

I copied this from wikapedia. I also searched for young's modulus numbers for 1144 and 0-1 but couldn't find any.

- rigidity and strength: the strength of material is characterized by its yield strength and / or its tensile strength;

- rigidity and stiffness: the beam stiffness (for example) depends on its Young's modulus but also on the ratio of its section to its length. The rigidity characterises the materials, the stiffness regards products and constructions: a massive mechanical plastic part can be much stiffer than a steel spring;

- rigidity and hardness: the hardness of a material defines its relative resistance that its surface opposes to the penetration of a harder body.

Another thing I ment to add earlier....HSS is available in round also. My van norman boring bars use a round HSS insert in the cutter carier.