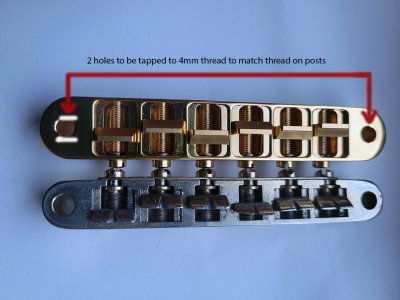

Hi I just registered on this site today. I am in London UK, a musician and have a small project. Attached is an image of my guitar bridge. The mounting holes on the bridge are too small for the support bolts on the body. They need to be tapped (prefferably) to match the 4mm bolts that I just purchased. The bolts are threaded into the wood (body) of the guitar thus I can only the mounting holes on the bridge can be modified. I'm in Beckenham, London and hope to find someone who is fairly close thus not to having to post the bridge. The old bridge is also in photo...showing that the new bridge holes are smaller. The brand new replacement (bridge mounting) posts I just got thread into the wood perfectly. The old mounting bolts are damaged. The mounting holes on the bridge are presently not threaded. If they were just widened that could work fine, but if threaded it should be better due to 100% transfer of vibration which equates to better tone (sound). I'm willing to negotiate a reasonable price for this service.

Thanks for replying ahead of time.

Barry

Thanks for replying ahead of time.

Barry