- Joined

- Feb 1, 2018

- Messages

- 1,867

It looks like you have your answer. Just don't do it like the shade tree mechanic.

Hi Mark, I am still a newbie. Plus, I thought it would be convenient to have a range of sizes already at hand, just in case.Hi Susan, John is correct- you have a lathe, you can probably make a small cylindrical tool to push the bearings out using a press. Or something press-like

mark

Hi Cadillac,You will need a puller to pull the bearings of the shaft of motor. A 2 jaw puller should work. To put them on either a press or pipe as stated touching only on the inner race.

Good luck.

Yup, mine looks like that, except the side pieces have a little surface rust. It also came with some sort of portable dust collector that you would place behind the wheel. I only got 1 so I'd have to move it to the other wheel if needed. Got these 2 items off craigslist for $40, and I made a friend from the seller. I told him I'd hook him up with a DC motor and PWM for his South Bend 9 for $100. I like to be nice to nice peopleHi,

Is this what you are referring too? https://www.mile-x.com/baldor-340-dental-lathe/

If so dismantle and will be a real simple job. Probably has standard size bearing and if just shielded I'd replace with -2RS.

About all you will need is a hammer and a pin punch.

Thanks Harry. That armature freezer suggestion sounds totally do-able. I will keep that in mind.As as motorcycle mechanic in my mid 20's to 30's I replace many a bearing drifting it in with a small drift punch taking care to not scar the shaft or touch the ball bearing. Light hammering the drift as you move it around the inner race slowly working it down.

Another method I have used replacing the bearing on a Craftsman 150 drill press motor was to put the armature in the freeze and place the new bearing on a small wattage candelabra light bulb to gently heat up the bearing. Then drift the bearing on per previous paragraph or find a suitable piece of iron pipe that will only put force on the inner race and slowly press/drift the bearing on.

Best of luck on learning something new!

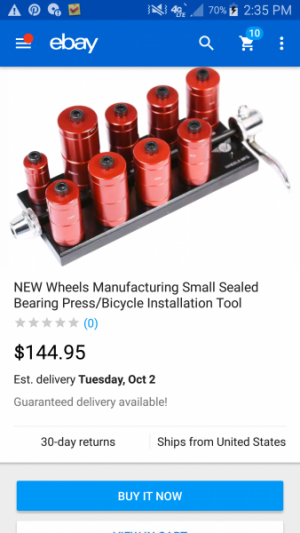

That is another reason why I want a proper set at hand.

That is another reason why I want a proper set at hand.Is it fixed yet[/QUOT

Ok, I will check it outSusan, look up "Baldor Motor Maintenance Lubrication Technology" on the net. Hope that will help. Mark