- Joined

- May 14, 2013

- Messages

- 104

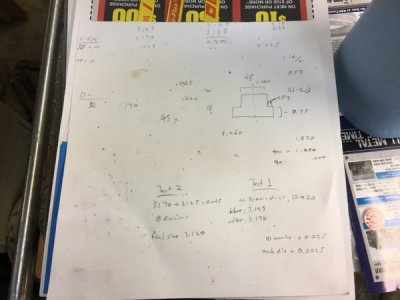

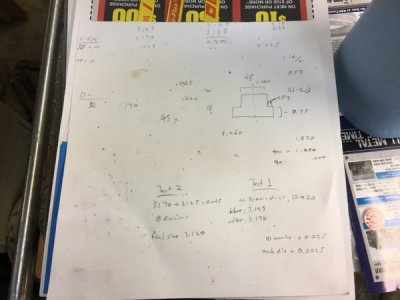

So what I learned is that from 0-10 (10 divisions) on the z-axis, you get 0.025mm cut - each individual division is 0.0025mm. Also learned the z-axis lock definitely helps! And as for 'why 60 divisions', I have no idea. To further confuse matters, the y-axis dial is 80 divisions, although same graduations.

So I was measuring 3.170, and needed to hit 3.125. That's 0.045, and equals 18 divisions. So I zeroed, turned 18 divisions, made the cut, and ended up with 3.120! \o/ Pretty sure the 0.005 difference was due to vise jaw lift, and either way, this is well within my expectations, especially given my newbieness.

The x- & y-axis dials are set with the same divisions, so now I just need to take the time to properly calculate my x and y cuts (match divisions vs. measurements), and I should be good to go! (also discovered I do not have a calculator, at least one I can find...)

Thanks everyone for the input, lots of lessons still to learn...

Scribbled notes

Need to be a little more systematic with my measurements...

Really need to learn to apply my z-axis learnings to the y-axis

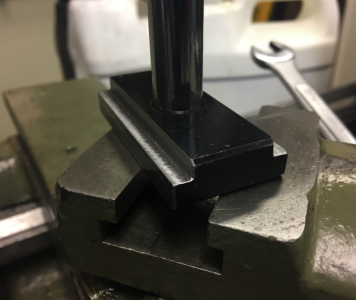

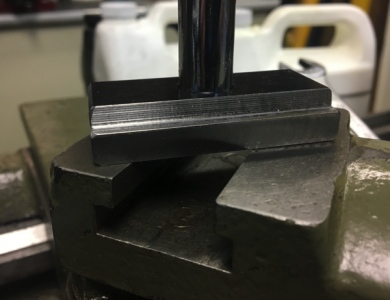

This is the part I have been working on - T-nut for my new AXA toolpost. Pretty sure I'll have to re-do it...but I think to start it should work. Still needs the threaded hole in the middle.

So I was measuring 3.170, and needed to hit 3.125. That's 0.045, and equals 18 divisions. So I zeroed, turned 18 divisions, made the cut, and ended up with 3.120! \o/ Pretty sure the 0.005 difference was due to vise jaw lift, and either way, this is well within my expectations, especially given my newbieness.

The x- & y-axis dials are set with the same divisions, so now I just need to take the time to properly calculate my x and y cuts (match divisions vs. measurements), and I should be good to go! (also discovered I do not have a calculator, at least one I can find...)

Thanks everyone for the input, lots of lessons still to learn...

Scribbled notes

Need to be a little more systematic with my measurements...

Really need to learn to apply my z-axis learnings to the y-axis

This is the part I have been working on - T-nut for my new AXA toolpost. Pretty sure I'll have to re-do it...but I think to start it should work. Still needs the threaded hole in the middle.