- Joined

- Oct 7, 2020

- Messages

- 2,362

@want2drive How much play does the original handle have? I would think it would be better to match the part that is attached to the mill. Is that part machined, in the photo it looks as though it is.

You said the handles fit in all directions and all locations. My guess is that the driven dog thing for the lack of proper terminology is machined, and the angles are 60°.

Now that being said. I'm just about as green as you, I only have a little over a year learning. And I have a lot to learn. What I think I would try is make a cardboard templet of the part that is on the mill. Blue up what the part I wanted to cut scribe some line on it and start cutting. I'm not saying that is the right way to do it, but that is what I would try.

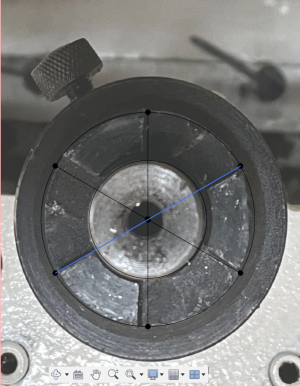

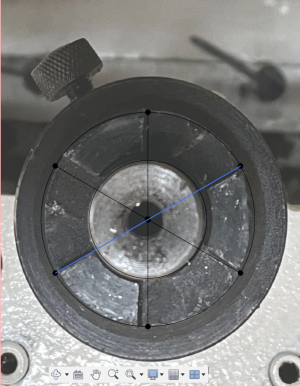

I've been playing with Fusion 360 like @Ischgl99 did with the handle. I can't say I'm doing it right but here is what I did the lines are evenly spaced at 60°. They don't line up just right, so, maybe the 60° is not right after all.

You said the handles fit in all directions and all locations. My guess is that the driven dog thing for the lack of proper terminology is machined, and the angles are 60°.

Now that being said. I'm just about as green as you, I only have a little over a year learning. And I have a lot to learn. What I think I would try is make a cardboard templet of the part that is on the mill. Blue up what the part I wanted to cut scribe some line on it and start cutting. I'm not saying that is the right way to do it, but that is what I would try.

I've been playing with Fusion 360 like @Ischgl99 did with the handle. I can't say I'm doing it right but here is what I did the lines are evenly spaced at 60°. They don't line up just right, so, maybe the 60° is not right after all.

Last edited: