- Joined

- Feb 1, 2015

- Messages

- 10,010

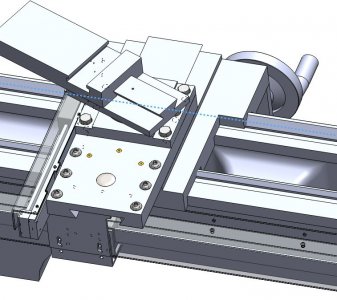

When I made my 6 bolt compound clamp for the 602, I also modified the cross slide by adding 6 more holes to the rear, along with the central bore for the compound. I had to set the the three oilers so they were below the surface of the cross slide as well. I can move my compound 4.5" to the rear which gives me more than enough travel for operations from the back side of the lathe.If I could figure out a way to mount a cut off tool from backside of my g0602, I'd be all over that.