- Joined

- Feb 1, 2015

- Messages

- 9,952

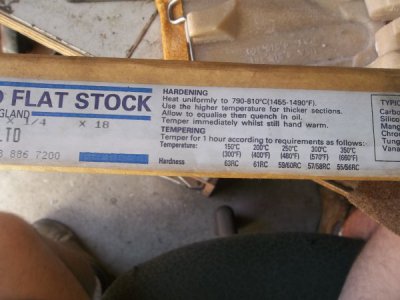

I run the colors for simple pieces like punches and chisels. Polish the work and slowly heat the struck end until the business end turns a faint yellow to straw color. I usually quench and repeat the process to make sure that I have it right. For a piece that needs to be uniformly hard , that process wouldn't work.

One point about running colors. The colors are the result of the buildup of an oxide layer and there is a time dependency. If the work is left to soak at a particular temperature, the color will darken. If pushed too fast, the work temperature will actually be higher than that indicated by the color.

I have two laboratory ovens, one of them forced air convection, and both have widely varying temperatures depending on location in the oven. If I wanted to hit 300F dead on, I would use an oil bath for tempering. Our deep fat fryer will hit 360ºF. Lead baths were used for tempering springs in the past.

My Extech multimeter came with a thermocouple probe which is ideal for monitoring temperature. Mine only goes to 1382ºF but others go as high as 1800ºF. A thermocouple has a fairly linear voltage vs. temperature curve and are readily available on e-bay. A simple thermometer could easily be made using the millivolt function on a multimeter. A two point calibration could be made and a graph plotted to convert millivolts to ºF. Well known points like the melting point of lead or various solders could be used for calibration. One consideration with a thermocouple is that it is measuring the temperature against your environment. If the environment temperature changes, the whole scale shifts. Probably not an issue in your case but something to consider.

One point about running colors. The colors are the result of the buildup of an oxide layer and there is a time dependency. If the work is left to soak at a particular temperature, the color will darken. If pushed too fast, the work temperature will actually be higher than that indicated by the color.

I have two laboratory ovens, one of them forced air convection, and both have widely varying temperatures depending on location in the oven. If I wanted to hit 300F dead on, I would use an oil bath for tempering. Our deep fat fryer will hit 360ºF. Lead baths were used for tempering springs in the past.

My Extech multimeter came with a thermocouple probe which is ideal for monitoring temperature. Mine only goes to 1382ºF but others go as high as 1800ºF. A thermocouple has a fairly linear voltage vs. temperature curve and are readily available on e-bay. A simple thermometer could easily be made using the millivolt function on a multimeter. A two point calibration could be made and a graph plotted to convert millivolts to ºF. Well known points like the melting point of lead or various solders could be used for calibration. One consideration with a thermocouple is that it is measuring the temperature against your environment. If the environment temperature changes, the whole scale shifts. Probably not an issue in your case but something to consider.