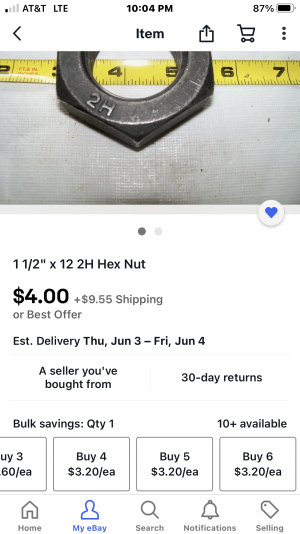

I got my part drilled an reamed:

View attachment 367464

The long mark is the high point of the eccentric. Jeff must have known my SB lathe has 3" travel on the tailstock when he designed this 3.14" part!

Next question: I have been reading about the difficulties for press fitting small dowel pins in blind holes. The tolerances are tight and the air has to go somewhere. Are there any objections to drilling out to 1/8" and using red Loctite?

Newbie question here, let me see if I understand this correctly I am making a jig to hold a part to contour mill with some 1/2" alum tooling plate. I am going to use .125" dia. dowel pins for alignment so I figure I will drill the holes with a #31 (.120") drill then ream with a .1247" reamer...

www.practicalmachinist.com

Otherwise should I use an oversize pin and a .1250 reamer or a .1250 pin and an undersize reamer? I have none in stock.

I think I am going to have to use my bolt hole calculator to drill the hub. Not sure how to hold this piece yet. It is kind of tall to hold in the mill vise with a V block.

Robert