- Joined

- Oct 20, 2014

- Messages

- 159

| material | rpm | diameter | feedrate | radial doc | sfm | lube | direction | chips | tool | notes |

| 303SS | 581 | 1.175 | .005 auto | .005 to .010 | 179 | WD40 | spindle | breaker | TPG322? | barely feel finish with nail |

| 303SS | 860 | 1.175 | .005 auto | .005 to .010 | 264 | WD40 | spindle | breaker | TPG322? | barely feel finish with nail |

Machine: Atlas 10F from 1940's

Stock held in 4 jaw chuck, center drilled and supported with live center in tailstock.

Stickout about 3" from chuck.

Insert: I think its a TPG322

thought i'd share..getting a good finish on steel is a small battle and I think this one I had a victory!

the good finish is in the middle..please ignore all the other, uh..."attempts"

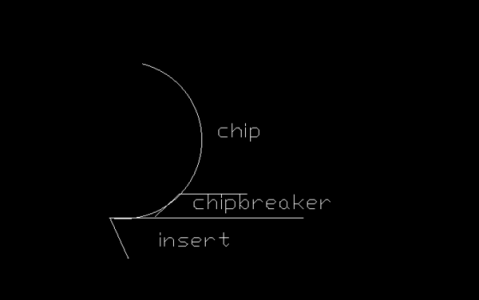

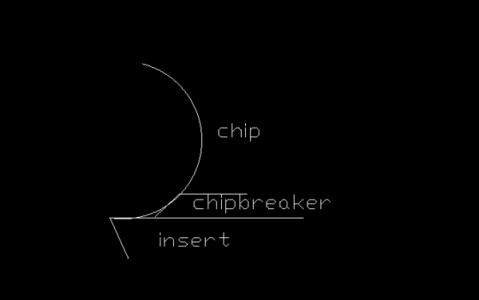

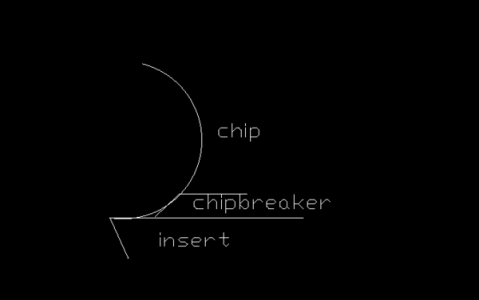

the carbide is an insert, with a fairly large radius, i'd say probably 1/32". The one visible in the picture with the sharp corners is the chip breaker installed on top of it, which doesnt actually cut the finish.

Last edited: