-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Goofs & Blunders You Should Avoid.

- Thread starter David S

- Start date

The place I work at now, when I started it was required that the engineers wear a tie. It only took me a couple of days to figure out that the engineers were also required to go out on the shop floor to assist and/or answer questions as well as work on prototype machine builds and testing. Of course I immediately lost the tie, when called out on it, I explained the perils of a tie in a shop as well as the history of a tie. Now there is no one in the company that wears a tie.

What is really scary is that the engineering manager then mentioned that he once got his tie caught by the lead screw on a lathe, lucky for him he was a very big strong guy and the machine was running at a slow enough speed for him to react, he was able to plant both hands on the machine and was strong enough to hold back till the tie broke and did not have his face pulled into the machine.

What is really scary is that the engineering manager then mentioned that he once got his tie caught by the lead screw on a lathe, lucky for him he was a very big strong guy and the machine was running at a slow enough speed for him to react, he was able to plant both hands on the machine and was strong enough to hold back till the tie broke and did not have his face pulled into the machine.

I had three blunders last night...

First, I went try to fix up a lathe backing plate (the threads on the L1 chuck weren't cut deep enough I think), got everything lined up and did a few cuts. I must have cut too deep on one of my runs, because the cast iron of the backing plate just started flaking off. Part ruined.

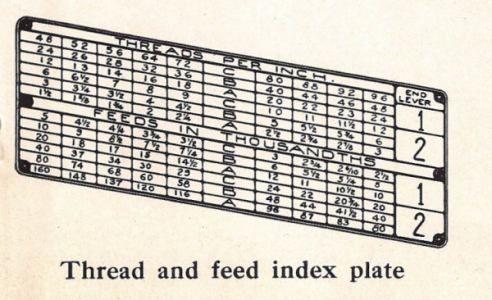

Second, I started trying to test out my ability to cut threads. I thought the above happened because my gearbox was wrong or something, so I configured my lathe to cut what I thought was 8 TPI this time (instead of 6). I cut about a half dozen test cuts, all ended up being about 6 TPI! I pulled a bunch of covers off of gearboxes, and couldn't figure out what the heck had happened! Only then did I look to the RIGHT of the '8' on the chart, and saw a '6 1/2'. Turns out my lathe has TWO '6' TPI locations (see 'C' with end lever 2, left position, B with end lever 2, right position) and the one on 'C' looks a heck of a lot like an 8

THEN, when testing out 12 TPI (minor screw up, I put the lever in 'A' instead of 'C', so was shocked to see 12 TPI result in 3 TPI), I forgot to take my chuck key out. I was in back gears so it happened slowly, but the key hit the carriage apron and sheared the 9/16" key right across. It was the least violent way I've seen something like this happen, but the 15HP lathe in backgears didn't even make a noise when tearing that key in half. If it wasn't for the end of the key falling out of the chuck and hitting the chip pan, it likely wouldn't have made a noise.

I then opted to just call it a night

First, I went try to fix up a lathe backing plate (the threads on the L1 chuck weren't cut deep enough I think), got everything lined up and did a few cuts. I must have cut too deep on one of my runs, because the cast iron of the backing plate just started flaking off. Part ruined.

Second, I started trying to test out my ability to cut threads. I thought the above happened because my gearbox was wrong or something, so I configured my lathe to cut what I thought was 8 TPI this time (instead of 6). I cut about a half dozen test cuts, all ended up being about 6 TPI! I pulled a bunch of covers off of gearboxes, and couldn't figure out what the heck had happened! Only then did I look to the RIGHT of the '8' on the chart, and saw a '6 1/2'. Turns out my lathe has TWO '6' TPI locations (see 'C' with end lever 2, left position, B with end lever 2, right position) and the one on 'C' looks a heck of a lot like an 8

THEN, when testing out 12 TPI (minor screw up, I put the lever in 'A' instead of 'C', so was shocked to see 12 TPI result in 3 TPI), I forgot to take my chuck key out. I was in back gears so it happened slowly, but the key hit the carriage apron and sheared the 9/16" key right across. It was the least violent way I've seen something like this happen, but the 15HP lathe in backgears didn't even make a noise when tearing that key in half. If it wasn't for the end of the key falling out of the chuck and hitting the chip pan, it likely wouldn't have made a noise.

I then opted to just call it a night

Attachments

Sounds like a plan!

Scary indeed that he didn't learn anything from the experience!What is really scary is that the engineering manager then mentioned that he once got his tie caught by the lead screw on a lathe, lucky for him he was a very big strong guy and the machine was running at a slow enough speed for him to react, he was able to plant both hands on the machine and was strong enough to hold back till the tie broke and did not have his face pulled into the machine.

Well, today I did something for the first time. I started the lathe with a key in the Jacobs spindle chuck. Naturally, I was in hurry and therefore Not Thinking. I lucked out: my VFD ramps up speed slowly, so the key just fell out into the chip pan

as it rotated around. No harm, no foul.

as it rotated around. No harm, no foul.

Way back when I was an apprentice, most of the older tradesmen wore a tie, some wore a waistcoat and even a jacket in colder weather. For the first two years we had to wear navy blue boiler maker overalls.

When we started 3rd year we were allowed to wear grey dust coats. same as some of the tradesman wore. Like a white lab coat but grey. They came in short sleeve for summer and long sleeve for winter but the sleeves had a button closure so they could be done up tight around the wrist for safety. These were normally worn over street clothes.

When we started 3rd year we were allowed to wear grey dust coats. same as some of the tradesman wore. Like a white lab coat but grey. They came in short sleeve for summer and long sleeve for winter but the sleeves had a button closure so they could be done up tight around the wrist for safety. These were normally worn over street clothes.

I like those old photos in popular mechanics where they are wearing long sleeved white coats, shirts and ties and smoking a pipe whilst doing something.

My Harrison M300 lathe operation manual has a picture of a machinist with a full length coat & a tie. My 300 is early green so I assume that it's a late '70 model Brit made.

Went to part of some stainless today.

WOW! the noise and screeching chatter, what the hell???

Checked the QCTP, no, thats all tight, all the gibbs are tight, saddle locked etc etc.

OK, just a quick look at the tool height but that should fine, I mean, I havnt changed the blade or anything.

WRONG, I replaced the plinth with the top slide to cut some tapers and the blade is now sitting 4mm lower.

Re set the height and it was back to nice long ribbons peeling off.

Phew! Glad I got that sorted.

WOW! the noise and screeching chatter, what the hell???

Checked the QCTP, no, thats all tight, all the gibbs are tight, saddle locked etc etc.

OK, just a quick look at the tool height but that should fine, I mean, I havnt changed the blade or anything.

WRONG, I replaced the plinth with the top slide to cut some tapers and the blade is now sitting 4mm lower.

Re set the height and it was back to nice long ribbons peeling off.

Phew! Glad I got that sorted.