- Joined

- Oct 5, 2024

- Messages

- 8

After getting my prolight mill up and running, I am ready to tackle the 3000 lathe

It has all of the original equipment including the control box and everything seems to be operational.

But the sliding tailstock will not slide. I have cleaned up the exposed track/bar, it had some modest surface rust that I suspect is also present under the tail stock and preventing motion. I have sprayed oil and rust preventative to no avail

Before I disassemble for cleaning, if that is the board's advice, I want to be sure that I won't have multiple parts/bearings come falling out that I won't be able to readily reassemble.

I can't find any documentation at intellitek, even the manual merely mentions the tail stock as an option without other info

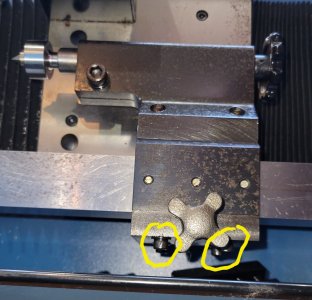

It appears that removing the bottom four bolts indicated will split the tail stock mount into two parts, allowing removal and access to the track interface and tailstock-innards for cleaning.

Is this sound? Does anyone have any insight on what I should expect on disassembly?

Also, are the three set screws for fine tuning the alignment?

It has all of the original equipment including the control box and everything seems to be operational.

But the sliding tailstock will not slide. I have cleaned up the exposed track/bar, it had some modest surface rust that I suspect is also present under the tail stock and preventing motion. I have sprayed oil and rust preventative to no avail

Before I disassemble for cleaning, if that is the board's advice, I want to be sure that I won't have multiple parts/bearings come falling out that I won't be able to readily reassemble.

I can't find any documentation at intellitek, even the manual merely mentions the tail stock as an option without other info

It appears that removing the bottom four bolts indicated will split the tail stock mount into two parts, allowing removal and access to the track interface and tailstock-innards for cleaning.

Is this sound? Does anyone have any insight on what I should expect on disassembly?

Also, are the three set screws for fine tuning the alignment?