-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Getting started: Shop questions

- Thread starter ArmyDoc

- Start date

- Joined

- Jul 8, 2018

- Messages

- 880

I built a shop last year in my barn. 12x24, and once I got the lathe, mill, and bench in, it was pretty full. Add shelving, stock, an area for reloading, a grinder and it was like moving about a submarine. I'd say double that (to 24x24) and then tack on the food processing area. 24x36 gives you an extra 24x12 to play with so it should be fine. The placement of your mill and lathe looks a bit tight on paper, but both of mine (a Bridgeport and a 14x40) fit in 24' with room to spare so it should be fine. Just do chalk outlines on the floor once you know the size of the machines, and ensure you have enough room to use and maintain them.

I went with a rotary converter for the 3-phase. The machines are not running 24/7 (or even 3/7, to be honest), so paying for 3-phase power would be a waste. It may sound blasphemous, but I find that most of the time in the shop is spent without the machines running: cutting and preparing material, doing setups, fit-and-finish, and of course repairing the machines.

Ditto what others said about insulation. I did R-30 rockwool on the roof of the shop (interior of barn), with some R-10 foam and plywood over that so the space can be used like an attic. R10 rockwool in the walls. One of those radiant oil-filled electric heaters for winter, and a mobile dehumidifier on a time with an outlet hose that runs through the wall. Humidity control is very, very important if you don't want all those tools to rust. This is a cheap, amateur setup compared to the more professional shops out there, but it does the job quite well.

Factor in all the supplemental equipment before you start: air compressor, grinder, band saw will be added to the shop eventually, so plan for them now. Decide on toolchests or pegboard now, since you can't make room for the pegboard later. The mess-making stuff like welding, grinding should be as far away from the machine tools as possible, but you can wall that area off with a welding curtain. I would probably do the welding and forging outside, in one of those lean-tos on your drawing, unless you plan to be doing lots of it.

Including the two machines, the riggers delivering them, and the material, I spent about 10K building the shop (a room inside a barn on an existing concrete slab). I'm sure I reached 20K by the end of the year, filling it with all sorts of additional tools.

I went with a rotary converter for the 3-phase. The machines are not running 24/7 (or even 3/7, to be honest), so paying for 3-phase power would be a waste. It may sound blasphemous, but I find that most of the time in the shop is spent without the machines running: cutting and preparing material, doing setups, fit-and-finish, and of course repairing the machines.

Ditto what others said about insulation. I did R-30 rockwool on the roof of the shop (interior of barn), with some R-10 foam and plywood over that so the space can be used like an attic. R10 rockwool in the walls. One of those radiant oil-filled electric heaters for winter, and a mobile dehumidifier on a time with an outlet hose that runs through the wall. Humidity control is very, very important if you don't want all those tools to rust. This is a cheap, amateur setup compared to the more professional shops out there, but it does the job quite well.

Factor in all the supplemental equipment before you start: air compressor, grinder, band saw will be added to the shop eventually, so plan for them now. Decide on toolchests or pegboard now, since you can't make room for the pegboard later. The mess-making stuff like welding, grinding should be as far away from the machine tools as possible, but you can wall that area off with a welding curtain. I would probably do the welding and forging outside, in one of those lean-tos on your drawing, unless you plan to be doing lots of it.

Including the two machines, the riggers delivering them, and the material, I spent about 10K building the shop (a room inside a barn on an existing concrete slab). I'm sure I reached 20K by the end of the year, filling it with all sorts of additional tools.

ThinWoodsman brings up a good point. How much space do you need around your lathe, mill etc? I have seen many people recommend NOT putting it right up against a wall, but rather leaving a couple feet so you can get be hind it for cleaning maintenance etc. But how do you estimate the work envelope around these machines?

Wow. Just found the section under members for shop posts. I had found several threads by searching for the keword "shop" etc, but never realized they were all gathered in one section. Sorry about that.

If one of the administrators wants to move this thread over there that's fine with me.

If one of the administrators wants to move this thread over there that's fine with me.

Well, it's been almost a year. Time to resurrect this old thread with an update and a few more questions. I had hoped to do the forestry harvest last year, but timber prices were in the toilet, and the harvest is what is paying for the shop. This past spring, prices were better so I signed a contract. Unfortunately with Covid-19 uncertainties, they insisted on a 1 year contract, so I don't know when it will be exactly. And of course timber prices have continued to go up sharply, so probably could have gotten an even better price now than 3 months ago. Isn't that always the way of it? In any case, it looks like I will be able to move forward in the next 6-9 months.

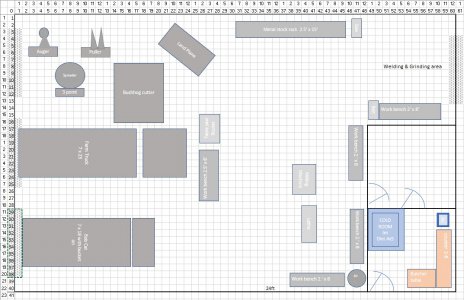

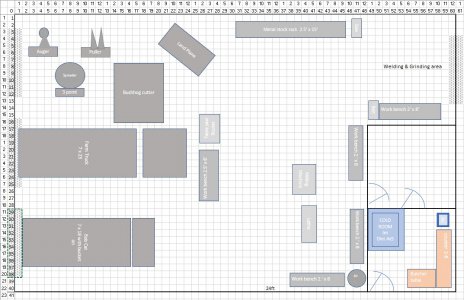

I've done some re-working and found it is less expensive to do one shed 40x60 than it is to do a central shop with two lean-toos on the sides. So, current concept is either a 40x60 or 40x72 with the front 1/3 or so used for equipment storage and the back 2/3 for the shop, something like this:

So, now for a few more questions.

So, now for a few more questions.

1) Having a hard time deciding if I want to enclose the area for ag storage (as shown), or just have that end open but covered and the exterior wall of the shop 2/3 of the way down the length of structure. Enclosed would be better because the equipment would be better protected, and if I ever want/need to expand the shop, I just move the equipment outside. The downside is trying to hook-up the implements to the bobcat inside the building is begging to damage the building at some point... If I do keep the implements inside, I can back the truck out the center, and that gives room to maneuver. Requires three doors though, and the doors have to be narrower. Thoughts?

2) Which do you think is better, steel frame building or a pole barn? If I go with steel frame, I have to get an engineered slab. If I go with pole barn, there are Poles every 10 or 12 feet along the long access. Both will span 40ft. Probably the steel frame is stronger... don't know. Any one have experience with both?

3) I have been looking at insulation options. One option is foam wood pannels. They are OSB on one side, foam on the other. Wood is 7/16 up to 5/8 thick, foam from an inch and a half up to 11 1/2 inches. https://www.bestmaterials.com/SearchResult.aspx?KeyWords=insullam Seems like it would be easy to put up, and provide the interior surface all in one step. Thoughts on this?

As always, I appreciate all of you guys input.

I've done some re-working and found it is less expensive to do one shed 40x60 than it is to do a central shop with two lean-toos on the sides. So, current concept is either a 40x60 or 40x72 with the front 1/3 or so used for equipment storage and the back 2/3 for the shop, something like this:

So, now for a few more questions.

So, now for a few more questions.1) Having a hard time deciding if I want to enclose the area for ag storage (as shown), or just have that end open but covered and the exterior wall of the shop 2/3 of the way down the length of structure. Enclosed would be better because the equipment would be better protected, and if I ever want/need to expand the shop, I just move the equipment outside. The downside is trying to hook-up the implements to the bobcat inside the building is begging to damage the building at some point... If I do keep the implements inside, I can back the truck out the center, and that gives room to maneuver. Requires three doors though, and the doors have to be narrower. Thoughts?

2) Which do you think is better, steel frame building or a pole barn? If I go with steel frame, I have to get an engineered slab. If I go with pole barn, there are Poles every 10 or 12 feet along the long access. Both will span 40ft. Probably the steel frame is stronger... don't know. Any one have experience with both?

3) I have been looking at insulation options. One option is foam wood pannels. They are OSB on one side, foam on the other. Wood is 7/16 up to 5/8 thick, foam from an inch and a half up to 11 1/2 inches. https://www.bestmaterials.com/SearchResult.aspx?KeyWords=insullam Seems like it would be easy to put up, and provide the interior surface all in one step. Thoughts on this?

As always, I appreciate all of you guys input.

Don't forget to install ventilation fans in the welding area. Some nasty fumes that should get out of the shop before they get in your lungs.

Steel frame is better than wood frame, it doesn't burn. However the cost is typically enough to give up on it.

For the equipment, hitching is more about is the door big enough. I'd get a bifold door the full length (or maybe a couple ones). Sliding doors cannot be insulated well and you will regret it. Overhead doors like a garage work but they take away ceiling space. Hydraulic doors that open out are good too (or so I think, I've never had first hand experience).

Make sure that the truck area has enough room overhead to put in a lift, and the concrete can support one. You might or might not do the type of project that needs one, but if you get into it you will be glad you made room.

Steel frame is better than wood frame, it doesn't burn. However the cost is typically enough to give up on it.

For the equipment, hitching is more about is the door big enough. I'd get a bifold door the full length (or maybe a couple ones). Sliding doors cannot be insulated well and you will regret it. Overhead doors like a garage work but they take away ceiling space. Hydraulic doors that open out are good too (or so I think, I've never had first hand experience).

Make sure that the truck area has enough room overhead to put in a lift, and the concrete can support one. You might or might not do the type of project that needs one, but if you get into it you will be glad you made room.

Steel does not burn.

Insurance way different price depending on construction.

Permitting pricing different dependent on use.

Do not mention welding when pulling permit as f2f gets craxy

Sent from my SAMSUNG-SM-G930A using Tapatalk

Insurance way different price depending on construction.

Permitting pricing different dependent on use.

Do not mention welding when pulling permit as f2f gets craxy

Sent from my SAMSUNG-SM-G930A using Tapatalk

Wasn't familiar with this kind of door. Nice, but expensive - at least from what I can find. Haven't asked for an actual quote.For the equipment, hitching is more about is the door big enough. I'd get a bifold door the full length...

Last edited:

- Joined

- Feb 6, 2020

- Messages

- 262

steel building with appropriate insulation

engineering concrete is not a big deal

you didn't mention height that i saw. if you go 16' you can put in a mezzanine later when you run out of space which you will if you do much

i would have at least one door 14x14 (electric) 10' wide gets pretty small bringing a large vehicle in

consider something like an inexpensive steel truss pole barn (roof only) as a separate building for your implements/trucks. your shop will fill fast

large suction fan in the back by welding area

at least double the electric receps you think you need - 120 & 240

lean-to off the back or side for air comp, wash sink...

i didn't see a welding table, extra light above that area

engineering concrete is not a big deal

you didn't mention height that i saw. if you go 16' you can put in a mezzanine later when you run out of space which you will if you do much

i would have at least one door 14x14 (electric) 10' wide gets pretty small bringing a large vehicle in

consider something like an inexpensive steel truss pole barn (roof only) as a separate building for your implements/trucks. your shop will fill fast

large suction fan in the back by welding area

at least double the electric receps you think you need - 120 & 240

lean-to off the back or side for air comp, wash sink...

i didn't see a welding table, extra light above that area