- Joined

- Feb 2, 2013

- Messages

- 3,957

i worked on the retainer yesterday and finished.

here is what i did to get there...

after rendering the cast iron slug from the saw

i center drilled and through drilled it to 5.5mm and reamed it to 6mm.

i set it up on a drilled and tapped M6x1.0 mild steel pedestal

i turned it eventually to concentric with the center bore, i took .010" cuts with HSS grind with a generous radius.

there was some interrupted cuts for about the the first .030",

then it started turning concentric and i took a couple skim cuts to ensure i was good.

i then went to facing the retainer

i hit a hard spot and had to switch to carbide after dulling the HSS a couple times at .010" DOC

i attacked a bit more aggressively with the carbide, and it straightened the problem right out

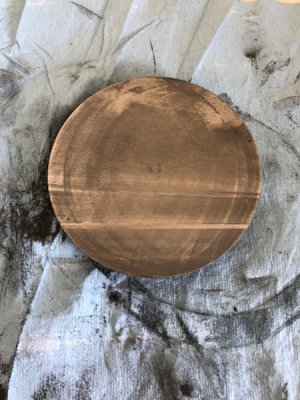

and here is the turned retainer!

the grinding wheel is a Cup Wheel- 8" in diameter X 4" Deep X 3/4" thick

1740 RPM grinding speed

i mounted the wheel today and took it for a test run.

less than .002" runout as indicated on the spindle on a 40+ year old grinder

i'll say it was a successful job

as always thanks for reading!

here is what i did to get there...

after rendering the cast iron slug from the saw

i center drilled and through drilled it to 5.5mm and reamed it to 6mm.

i set it up on a drilled and tapped M6x1.0 mild steel pedestal

i turned it eventually to concentric with the center bore, i took .010" cuts with HSS grind with a generous radius.

there was some interrupted cuts for about the the first .030",

then it started turning concentric and i took a couple skim cuts to ensure i was good.

i then went to facing the retainer

i hit a hard spot and had to switch to carbide after dulling the HSS a couple times at .010" DOC

i attacked a bit more aggressively with the carbide, and it straightened the problem right out

and here is the turned retainer!

the grinding wheel is a Cup Wheel- 8" in diameter X 4" Deep X 3/4" thick

1740 RPM grinding speed

i mounted the wheel today and took it for a test run.

less than .002" runout as indicated on the spindle on a 40+ year old grinder

i'll say it was a successful job

as always thanks for reading!