- Joined

- Jun 26, 2018

- Messages

- 1,733

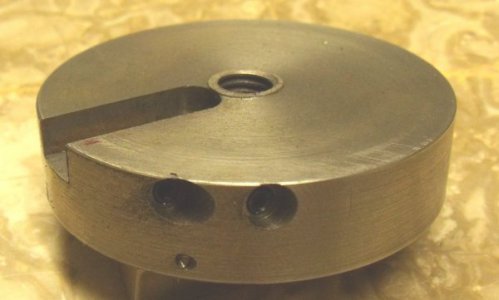

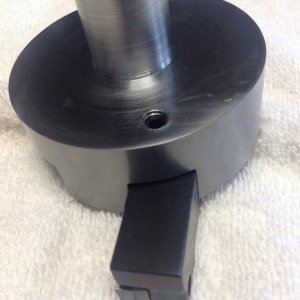

I haven't started yet, i am posting in this category as I am sure many of you have already made one. I've done a lot of searching in regards to cutter angle on the fly cutter, how big of a circle should i shoot for being able to surface in one pass? Im sure it will come up, this is for a PM 737 (1 hp) seems like blade should be 30 to 60 degrees in relation to material.

There are so many different designs, I just dont know what is practical with my machine's capabilities (or mine for that matter) I like the style where a bar passes through the flycutter and by adjusting the bar in/out, you greatly change the diameter of the cut.I

Getting into the details about actual cutter and all its angles is a whole other Oprah...I will be going HSS over indexable carbide.

Anyway, any incite into this project before I jump in would be greatly appreciated.

There are so many different designs, I just dont know what is practical with my machine's capabilities (or mine for that matter) I like the style where a bar passes through the flycutter and by adjusting the bar in/out, you greatly change the diameter of the cut.I

Getting into the details about actual cutter and all its angles is a whole other Oprah...I will be going HSS over indexable carbide.

Anyway, any incite into this project before I jump in would be greatly appreciated.