- Joined

- Mar 26, 2018

- Messages

- 8,756

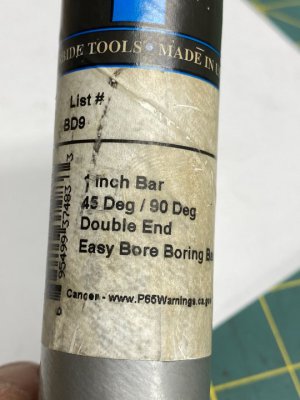

I bought this boring bar a while back, first time I had a need.

I’m making a spider for the back of my spindle.

It worked fantastic. Rock solid.

I used the Aloris standard CXA holder.

If you need one, I endorse this one.

I’m making a spider for the back of my spindle.

It worked fantastic. Rock solid.

I used the Aloris standard CXA holder.

If you need one, I endorse this one.

Attachments

-

3FD06523-67A7-4F06-9E33-414B817D9B51.jpeg69.7 KB · Views: 59

3FD06523-67A7-4F06-9E33-414B817D9B51.jpeg69.7 KB · Views: 59 -

413563A3-077F-4D76-988E-BCFAC0356810.jpeg83.9 KB · Views: 60

413563A3-077F-4D76-988E-BCFAC0356810.jpeg83.9 KB · Views: 60 -

88F4C42F-2AD1-4B9B-8697-97DED7391728.jpeg67.7 KB · Views: 57

88F4C42F-2AD1-4B9B-8697-97DED7391728.jpeg67.7 KB · Views: 57 -

9C73C5DF-E6E5-46E9-8D31-F73742AE6937.jpeg40.7 KB · Views: 54

9C73C5DF-E6E5-46E9-8D31-F73742AE6937.jpeg40.7 KB · Views: 54 -

016AF1BB-2517-4521-8434-7C6633E85613.jpeg34.6 KB · Views: 53

016AF1BB-2517-4521-8434-7C6633E85613.jpeg34.6 KB · Views: 53 -

8994D1BB-FAD6-42A5-99A1-9B6AD250BC1C.jpeg89.7 KB · Views: 51

8994D1BB-FAD6-42A5-99A1-9B6AD250BC1C.jpeg89.7 KB · Views: 51 -

C6EEA77A-201D-4929-BC97-E7DFC115C3F6.jpeg81.9 KB · Views: 47

C6EEA77A-201D-4929-BC97-E7DFC115C3F6.jpeg81.9 KB · Views: 47 -

D9ED389C-8E02-465A-9E3B-6E1B87F1DE21.jpeg109.1 KB · Views: 54

D9ED389C-8E02-465A-9E3B-6E1B87F1DE21.jpeg109.1 KB · Views: 54