- Joined

- Nov 6, 2021

- Messages

- 60

I 'needed' a brass pull for an application in my workshop. I didn't really 'need' it but I was looking for an excuse to try freehand turning on my recently acquired 7x16 mini Lathe. I looked into getting a Turnado, but thought I should, at least, give it a try with tools on hand.

I figured a flat carbide Easy Wood bowl gouge with a small diameter tip (Ci5 using Easy Wood's nomenclature) should be relatively easy to guide around a brass bar. So, holding the gouge edge even with the tailstock center I was very pleasantly surprised that the distance from the bottom of the gouge to the cross slide was exactly 2". Perfect! I could use a 123 block as a tool rest!

So, taking the compound off the cross slide and using a Magnetic holder, I came up with this:

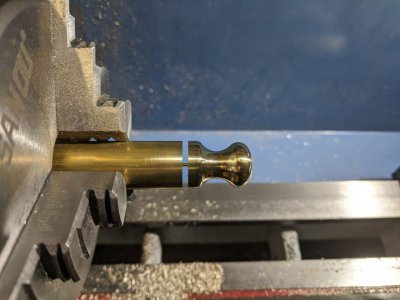

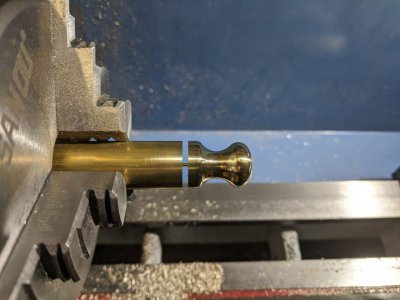

And after a bit of turning, sanding, and polishing, I ended up with this!

I do need to figure out how to drill and tap the base, but, what the heck, this feels like a good start to me!

I did get some chatter after I had cut the neck most of the way. It sanded out easily, but I'd like to avoid it in the future. More practice I guess...

Deets: Turned around 920 RPM, no lubricant. The brass cut pretty nicely with the gouge, but I think I'll get a small one to dedicate to the task and also be able to use Easy Wood's detail bit. The bit was a used bit, but it seemed sharp enough for this task.

I figured a flat carbide Easy Wood bowl gouge with a small diameter tip (Ci5 using Easy Wood's nomenclature) should be relatively easy to guide around a brass bar. So, holding the gouge edge even with the tailstock center I was very pleasantly surprised that the distance from the bottom of the gouge to the cross slide was exactly 2". Perfect! I could use a 123 block as a tool rest!

So, taking the compound off the cross slide and using a Magnetic holder, I came up with this:

And after a bit of turning, sanding, and polishing, I ended up with this!

I do need to figure out how to drill and tap the base, but, what the heck, this feels like a good start to me!

I did get some chatter after I had cut the neck most of the way. It sanded out easily, but I'd like to avoid it in the future. More practice I guess...

Deets: Turned around 920 RPM, no lubricant. The brass cut pretty nicely with the gouge, but I think I'll get a small one to dedicate to the task and also be able to use Easy Wood's detail bit. The bit was a used bit, but it seemed sharp enough for this task.