- Joined

- Jun 12, 2014

- Messages

- 5,080

It is not only the DOC but also the feed rate, with chromoly steels you need higher feed rates, typically in the .008-.012 IPR. You need to engage at least 1/2 the nose radius of the cutter, and the type of insert/holder makes a significant difference. As the DOC increases and feed rate, the rigidity of the lathe becomes more of a factor. With 4140 it is very hard to get chips, it takes much higher speeds, DOC and feed. With 1018 it is hard to get a decent finish, lots of factors. Biggest mistake I made early on with turning was not enough feed.

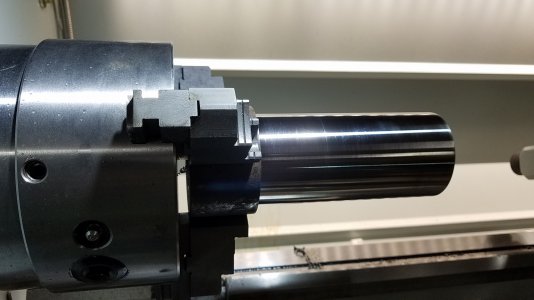

Difference with 4140 going from .004 to .008 IPR.

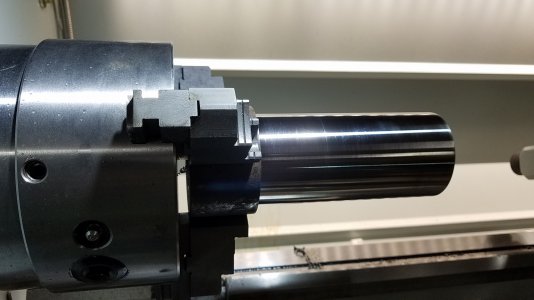

Final dimension pass at the higher feed rate, roughing passes were ~0.1"DOC and final pass in the range of 0.050". The line at 2/3rds of the pass is when the swarf was so long that I needed to stop the feed to break it, must have been 25' long . When I was boring the center I was able to get chips in 1-2" lengths because the insert was a CPMT, but the swarf would jam in the chuck/spindle.

. When I was boring the center I was able to get chips in 1-2" lengths because the insert was a CPMT, but the swarf would jam in the chuck/spindle.

Boring bar is 1" carbide boring to 8" depth, was able to maintain 0.001 from start to finish without chatter.

Difference with 4140 going from .004 to .008 IPR.

Final dimension pass at the higher feed rate, roughing passes were ~0.1"DOC and final pass in the range of 0.050". The line at 2/3rds of the pass is when the swarf was so long that I needed to stop the feed to break it, must have been 25' long

Boring bar is 1" carbide boring to 8" depth, was able to maintain 0.001 from start to finish without chatter.