- Joined

- Sep 7, 2019

- Messages

- 674

Hey, I'm seeking advice on filler selection for a part from an Atlas shaper.

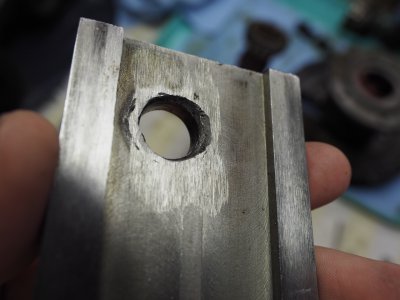

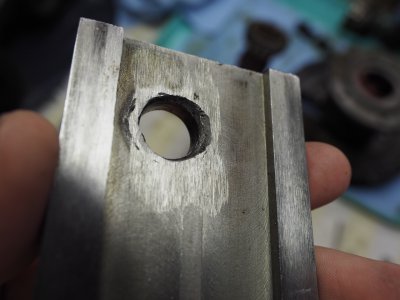

There's a pin pressed into a plate. The back side is welded and ground flush.

In the pic below I've already begun pressing it out. The flushed off weld had cracked around 90% of the circumference.

The front side receives no weld.

The pin is most likely some kind of tool steel.

I'm not sure about the plate being tool steel. It probably should be for the service it does, but none of the surfaces are finished as finely as the pin. Some scoring can be seen in the sliding fit parts so it may not be a very hard steel.

In the little research I've done some have suggested specialty tool steel rods. Others say 309L is a good choice. Some have said 7018. Most agree that pre/post heating and ample peening is a good idea. I've even heard that you could avoid all the metallurgical intricacies by brazing instead of welding when it comes to tool steel.

So what are your thoughts?

There's a pin pressed into a plate. The back side is welded and ground flush.

In the pic below I've already begun pressing it out. The flushed off weld had cracked around 90% of the circumference.

The front side receives no weld.

The pin is most likely some kind of tool steel.

I'm not sure about the plate being tool steel. It probably should be for the service it does, but none of the surfaces are finished as finely as the pin. Some scoring can be seen in the sliding fit parts so it may not be a very hard steel.

In the little research I've done some have suggested specialty tool steel rods. Others say 309L is a good choice. Some have said 7018. Most agree that pre/post heating and ample peening is a good idea. I've even heard that you could avoid all the metallurgical intricacies by brazing instead of welding when it comes to tool steel.

So what are your thoughts?