Shoot, I still can't believe that Sears (the pre-Kmart Sears) isn't around any longer. I suspect I'd have gone new as well if they were.

I'm still not 100% confident that I understand what pre-loading is or does, though. Please validate if my understanding jibes with yours.

If I understand correctly what you and

the engineerlive.com article that Henry provided are saying (a very big "if") then the normal way to spring pre-load this type of rotating spindle would be to have shoulders on the spindle or some other mechanical way to prevent the two bearings from moving toward each other axially. The shoulders would bear on the inside faces of the inner races, and springs (or Belleville washers) would bear on the outer faces of the outside races. This would cause the inside and outside races of each bearing to offset minutely, apparently taking up internal clearance between the balls and the races. This is what

the nmbtc article refers to as "duplex face-to-face" preload.

I'm basing this understanding on your comment about not seeing a valid reason for the Belleville washer in my lathe since the rear bearing floats axially, and from the following two sentences

from the engineeringlive.com article:

For mounting, the spring is normally applied to the non-rotating part of the bearing, typically the outer ring.

and

Axial adjustment calls for the mounting of at least two bearings in opposition, so that inner and outer rings of each bearing are offset axially.

Here's what I think I was missing:

I'd always visualized bearings as having the balls running on flat races, but if I understand correctly (that "if" again) the balls actually ride in a curved groove in the races. So when the inner and outer races are offset axially, the balls are more tightly squeezed in the races (both axially and radially!).

If I've got it right, then "pre-loading" bearings just means minutely offsetting the inner and outer races of a bearing axially to remove internal clearances. This works because the ball bearings ride in groove, not on flat races.

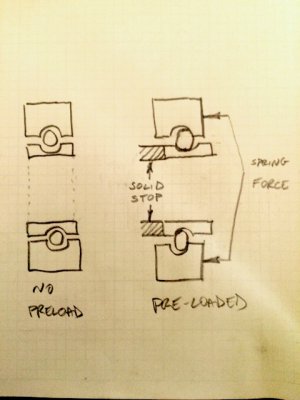

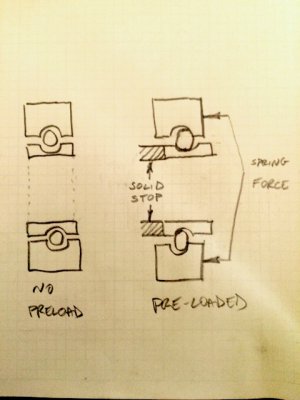

Visually, here is what I think pre-loading means (a cross-section looking at a bearing on edge). Please let me know if I've got it right (finally!).

If this is correct, then I understand your comment that the Belleville washer in my lathe must be there for some reason other than pre-loading. Because both the solid stop (the clip-ring) and the spring (Belleville) bear on the outer race, the inner and outer races aren't being offset.

Sorry for prolonging this thread so long, but I figure if I'm this confused by the term "pre-loading" then I'm probably not alone. The conversation has improved my understanding of my lathe immensely. I hope it's useful for others.

On a sadder note, while the play at the spindle itself was greatly reduced, I'm still getting a few thou of play at the chuck jaws. I'm still getting a lot of chatter when parting a chucked piece (but parting with collets works a treat). It's more than possible I'm still doing something wrong, but several thou of play at the chuck jaws can't be helping.

Regards,

--

Rex