Hi. Thanks for the offer and information. These are community consumables, and have to be left in the shop. When I need to get something done, I have my own end mills that I got at a garage sale. They are name brands, in excellent condition, and seem to perform well. Most of the other people using the mills bring their own bits, and have favorites. Most of them use generic carbide end mills that they get online, such as at Enco, since these seem to provide the most bang for the buck. I am afraid that I am still too much in the beginner stage for that right now.

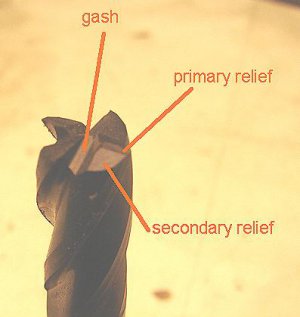

The past weekend, I looked at the milling machine community box and noticed that someone had gashed the end mills that I attempted to sharpen. I think that I have the geometry down now, and further experimentation might prove fruitful. From what I saw, gashing is pretty straightforward if the end mill can afford to lose any center cutting ability. Just make an x in the end with the corner of the wheel. The wheel must be dressed sharp. As mentioned above, it is challenging for carbide, since the green wheel at TechShop is never dressed sharp.

The past weekend, I looked at the milling machine community box and noticed that someone had gashed the end mills that I attempted to sharpen. I think that I have the geometry down now, and further experimentation might prove fruitful. From what I saw, gashing is pretty straightforward if the end mill can afford to lose any center cutting ability. Just make an x in the end with the corner of the wheel. The wheel must be dressed sharp. As mentioned above, it is challenging for carbide, since the green wheel at TechShop is never dressed sharp.